Fillers (or filling machine) are used for packaging, mainly for liquid or paste, like water, juice, milk, perfume and ketchup etc. According to the degree of automation, they can be divided into manual filling machines, semi-automatic filling machines and fully automatic filling machines.These are used to fill either a bottle or a pouch, depending on the product. There are several types of fillers used by the packaging industry.

Filling Equipment For Different Filling Material

Popular Related Categories

Learn More About Filler Machine

Types of Filling Machine

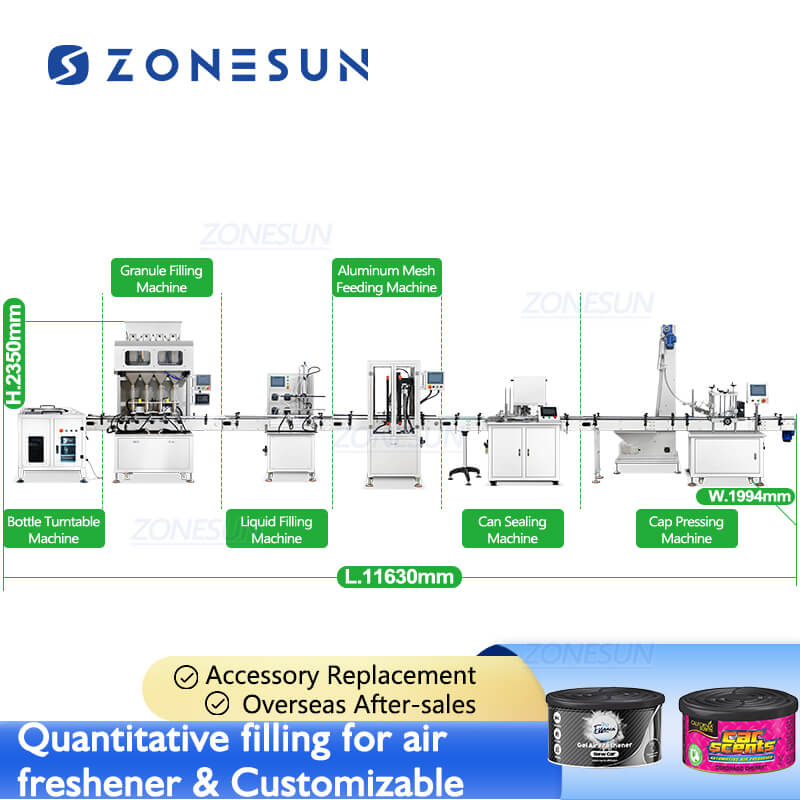

Filling machines can be classified from multiple dimensions, primarily including automation level, type of filling material, filling principle, and container type. Below is a detailed breakdown of these dimensions:

By Automation Level

- Manual Filling Machines: Simple to operate, suitable for small-scale production or laboratory use.

- Semi-Automatic Filling Machines: Combine manual and automatic operations, suitable for small to medium-scale production.

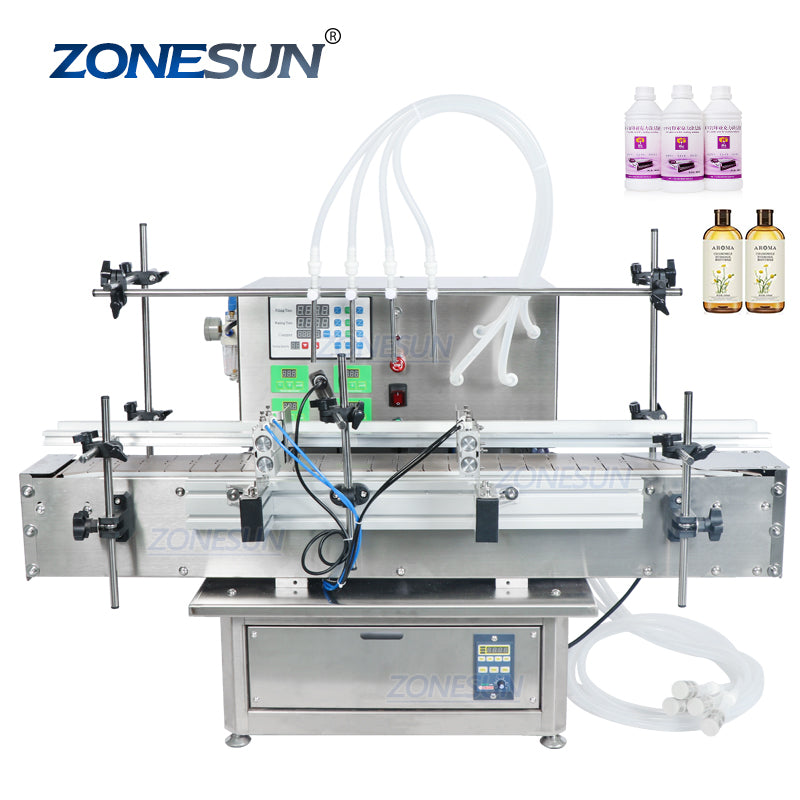

- Fully Automatic Filling Machines: Fully automated, suitable for large-scale production, improving efficiency and consistency.

By Working Function

- Inline Filling Machine

- Monoblock filling and capping machine( for bottles)

- Monoblock filling and sealing machine (for cup/tube/bag)

By Type of Filling Material

- Liquid Filling Machines: Used for low-viscosity liquids such as water, juice, and oil.

- Paste Filling Machines: Suitable for high-viscosity materials like honey, toothpaste, and jam.

- Powder Filling Machines: Used for powdered products such as milk powder, seasoning powder, and chemical powders.

- Granule Filling Machines: Suitable for solid materials such as granules, capsules, and candy.

By Filling Principle

- Gravity Filling Machines: Utilize gravity to fill containers with liquid, suitable for low-viscosity liquids.

- Volumetric Filling Machines: This kind of filling machinery can ensure each container receives same volume of filling material, common measuring type is the piston pump filling machine(Using reciprocating motion of a piston to fill), the lobe pump filler (Transferring the product through cavities formed by a pair of synchronized lobes rotating inside the pump chamber), the flowmeter filling machine (Real-time monitoring of the fluid flow through a flow meter)

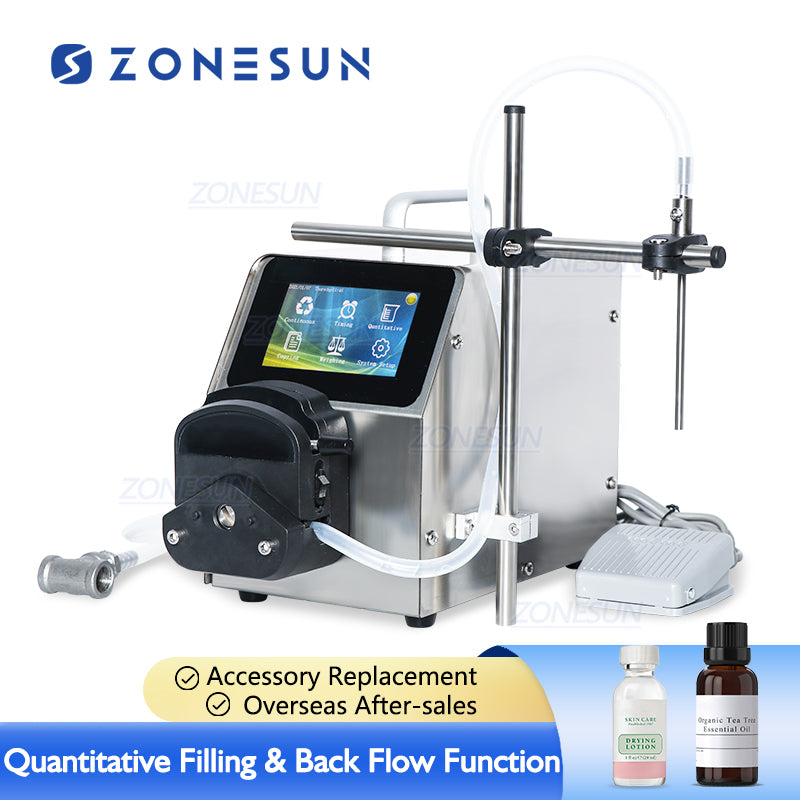

- Pump Filling Machines: Use various types of pumps (magnetic pump, gear pump, peristaltic pump, etc.) for filling, suitable for liquids of all viscosities.

- Overflow Filling Machines: Ensure that containers are filled to a consistent level, suitable for transparent containers.

By Container Type

①Bottle Filling Machines: Suitable for various shapes and sizes of glass or plastic bottles. Regularly the user simply inputs amount of time necessary or filling volume to fill the bottles(depends on the machine is controlled by digital timer or servo system)

Filling machinery will be different when using in different sizes or different shapes of bottles. The most common challenges and considerations are as below:

For Large Bottle Filling Machine

Larger filling volume are required, therefore piston pumps, rotor pumps, or flowmeter-based systems are often used to ensure stable and accurate dosing. Common packaged produccts are includes detergents, lubricants, engine oil and household cleaning products. Since these containers are heavier, the conveyor width, length, and load-bearing capacity must be carefully designed to support production needs.

For Small Bottle (Vial) Filling Machinery

Manufacturer need to pay more attention when choosing a bottle filling machine for vials.During transportation, some small bottles may not remain upright, which makes it necessary to use customized fixing molds to keep them upright during automatic filling work. Another option is choosing the filling machinery with cross-filling function.These machines are often chosen for packaging high-value products like skincare serums, essential oils, eye drops, or face creams. To achieve precise filling and minimize material waste, peristaltic pumps, ceramic pumps, or magnetic pumps are commonly used.

For Irregular Shaped Bottle Filling Machine

For irregular-shaped bottles, bottle filling machinery often needs to be customized according to bottle specific dimensions. Customized packaging solution can ensure filling work remain accurate.

②Bag Filling Machines: Suitable for different types of bags such as stand-up pouches, pillow bags, etc.Pouch can be divided into premade pouch or roll film bags.Regularly this kind of packaging type will need machine has the function of sealing at the same time. Heat sealable packaging film of these two kinds of bags will be good for bag sealing. Sealing type also is various.

③Cup Filling Machines: Used for filling liquid or paste into cups like dipping sauce, commonly used in the food and beverage industry.

④Tube Filling Machines: Used for packaging paste or gel products in tubes, such as cosmetics and pharmaceuticals.

Key Features and Considerations

- Viscosity of the Product: Determines the type of filling machine and the filling speed.

- Production Volume: High-volume production lines may require fully automated systems, while lower volumes might use semi-automatic or manual machines

- Accuracy and Precision: Essential for reducing waste and ensuring product consistency.

- Working Capacity: Determines the production rate, with high-speed machines suitable for large-scale operations.

- Versatility: Ability to handle various product types and container sizes.

- Ease of Cleaning and Maintenance: Important for hygiene and minimizing downtime.

Working Capacity Of Filling Machine

In the process of providing customers with suitable packaging production solutions, one of the most common questions we encounter is "How many bottles/bags can this machine produce per day/hour/minute?" There are several factors that affect work efficiency, such as the degree of automation of the filling machine, filling volume, characteristics of the filling material, type of bottle, etc. Only after providing specific material information and production requirements, can we give a definite data answer.

Key Common Features Of Filling Machines

Anti-dripping Filling Nozzles: It can be customized to handle different viscosities and to prevent dripping or splashing.

Diving Filling Nozzles: Designed for preventing foamy liquid from splashing out during filling work

Food Grade Stainless Steel Construction: Meet sanitary standards, crucial for food and pharmaceutical applications.Good for jam, hot saue, honey, cough syrup etc.Enhances durability and eases cleaning, maintaining hygiene standards.

Adjustable Settings: Allows for control over filling speed and volume(servo system filling machine), catering to different container sizes and production needs

Custom Hopper: A reservoir that holds the paste product before dispensing filling material. Heating and stirring mechanism can be customized for keeping the paste uniformly mixed.

PLC Control Systems: Offer user-friendly interfaces for setting and monitoring machine parameters.Different kindso f operation language can be customized

Maintenance And Support For Filling Machines

We provide maintenance services, training, and support to ensure the optimal performance of filling machines. like

One-year Warranty: Free replacement of parts within the warranty period, except for easily damaged parts. Out of the warranty period, you can still contact us for any questions about the machine (machine maintenance, parts purchase)

After-sales Service: Offer user manual, install &debugging video, one-to-one video chat, oversea after-sales service( in some area)

Oversea Warehouse: Some machines can be shipped from overseas warehouses to reduce delivery time and cost.

Custom Packaging Solution: Offer one-stop packaging solution through detailed packaging production need.

FAQ of filling machinery

Q1: Can one bottle filling machine handle multiple bottle sizes?

Yes. For inline bottle filling machine, you may need slight adjustment of Most bottle filling machines are designed with adjustable settings or changeable molds, allowing them to handle different bottle diameters and heights. For irregular-shaped bottles, customized solutions are often required.

Q2: Can a volumetric filling machine work with both liquids and pastes?

A: Yes, but the configuration depends on the filling material characteristics. For highly viscous materials, a volumetric filler with a rotor pump is usually recommended. For medium-viscosity products like detergents, lotions, or shampoos, a piston pump system will be better. If you need one machine to handle both liquids and pastes, ZONESUN customized solution will be offered to ensure accurate filling and stable performance.