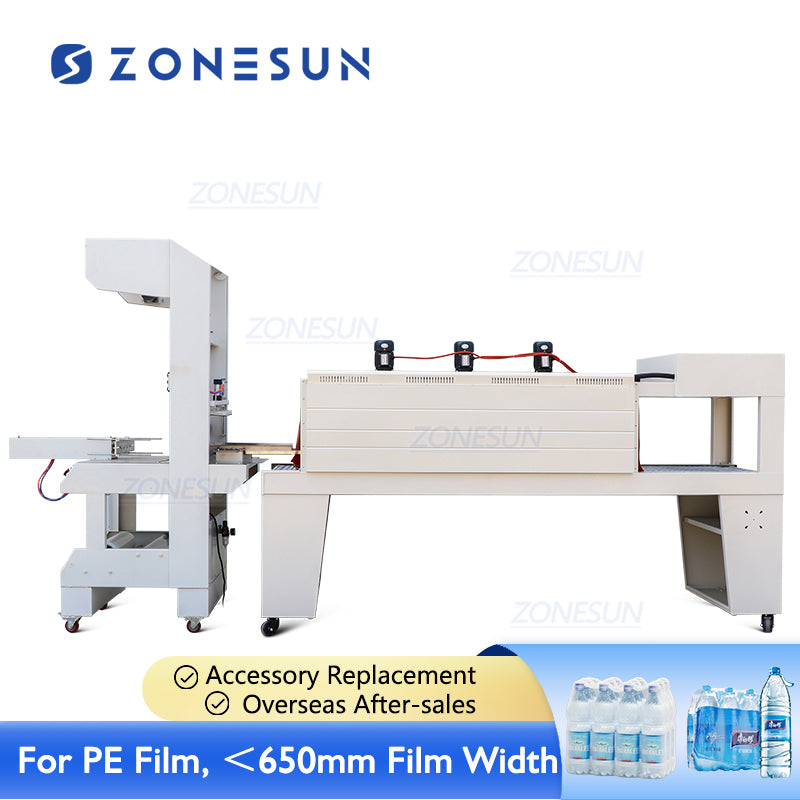

We offers manual shrink sealers, chamber-type shrink wrapping machine, manual L sealers, automatic L sealing machine, automatic side-seal machine, sleeve wrapping machine, heat shrink packaging tunnels, and combination shrink packaging systems.They are good for various packaging includes paper boxes, bottles, cans and others.

What is a shrinking machine?

A shrinking machine, often referred to as a shrink machine or shrink wrapping machine, is a piece of equipment used for packaging and securing products by tightly wrapping them in a plastic film or shrink film and then applying heat to shrink the film, creating a tight, and conforming seal around the product. We not only provide shrinking machines,L sealing machines and side-seal machine for packaging daily supplies or paper boxes , but also sleeving machines, shrink band (wine capsule)shrinking machine for anti-tampering of bottles. Shrink machines are commonly used in various industries for packaging a wide range of products, including consumer goods, food and beverages, industrial items, and more.

Types of packaging film

The applicable packaging film of shrinking machine are different based on packaging products and packaging type.

They are generally suitable for PP/POF/PVC, and some are suitable for PE /PET/OPS packaging film.

Heating method of heat shrinking tunnel

Shrink machines can be divided into jet shrink wrapping machines, direct heat shrink wrapping machines (heated by infrared tube), internal circulation shrink machines, etc. The heating method of shrinking machine should be chosen based on packaging products type and size.

Working capacity of heat shrink wrapping machine

The working capacity of a shrink sleeve labeling machine depends on factors such as production speed, container size and shape, film type and thickness, operational efficiency, and machine configuration(such as tunnel size. The level of automation and maintenance also affects capacity. Choosing the right machine requires considering production needs and machine specifications.We offer different size of heat shrink wrapping machine for meet differernt packaging requirement.

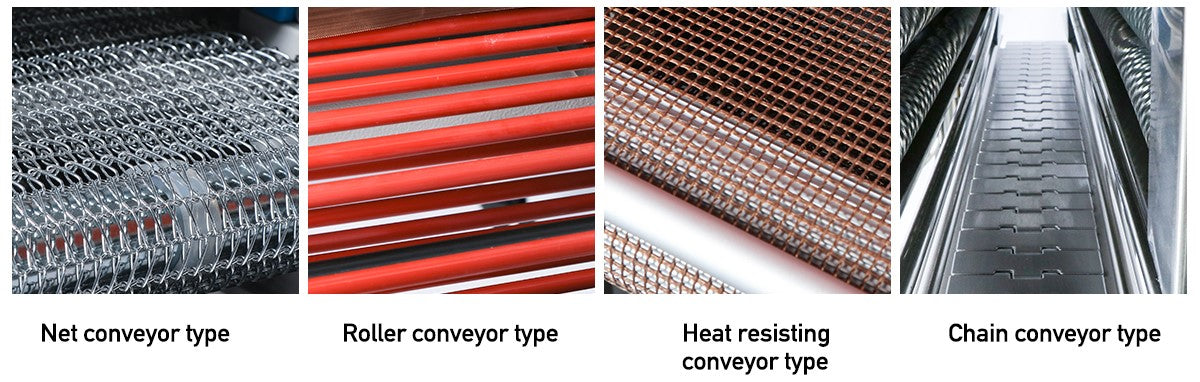

Conveyor of heat shrinking tunnel

Net conveyor type

The galvanized mesh or stainless steel mesh is mainly used, and the metal mesh belt passes through the heat shrinking machine. Because the metal is in fast heat conduction and in high temperature, when the product with a large bottom contact area is placed on the mesh belt, the film will be made with gridding marks, especially for thePOF shrink film, the shrinking effect will be not good.Products with small bottom contact area is suitable for this kind of conveyor,such as tableware ,irregular products

Roller conveyor type

The middle of the roller is put with spring steel strips. The heat-resistant silicone tube on the steel strip can block heat, and will not make the film deformed. The shrinkage effect is very good, the gap between the rollers is 2cm, and the round product can be stuck in the gap.When the conveyor belt rolls, the shrinking effect will be better.The product with a large contact area is suitable for this shrinking machine.

(PTFE) Heat resisting conveyor type

It is a high-performance multi-purpose composite new material. It can adapt to small products and will not burn the film. It is the best shrinking mesh belt in the market These three types of conveyor can be customized based on production needs.and they are usually used for block, box or tray packaging products.

Chain conveyor type

Suitable for heavier materials or products that need to be transported stably, such as bottled beverages, and chain conveyor are usually resistant to high temperatures and wear, suitable for large-scale production lines that work at high temperatures or for long periods of time. In addition, it is easier to integrate with other packaging machinery to form a complete packaging system

How to use a shrink machine?

To use a shrink wrapping machine effectively, First, make sure the machine is set up correctly. It should be noted that the power connection of the shrink machine is through a circuit breaker rather than a common power plug. After purchasing the machine, we will tell you how to wire it correctly. After this, the film is loaded correctly. Adjust the machine settings, including temperature, conveyor speed, and air flow, based on the film type and product specifications. Position the product inside the shrink film, ensuring a secure seal. Start the machine, allowing the product to pass through the heat tunnel while monitoring the process for even shrinkage. After the product cools, inspect the wrap for quality, and perform regular maintenance to keep the machine in optimal condition.

Do you provide maintenance and support for shrink wrapping machines?

Yes, we provide maintenance services, training, and support to ensure the optimal performance of shrink wrapping machine. like

One-year Warranty: Free replacement of parts within the warranty period, except for easily damaged parts. Out of the warranty period, you can still contact us for any questions about the machine (machine maintenance, parts purchase)

After-sales Service: Offer user manual, install &debugging video, one-to-one video chat, oversea after-sales service( in some area)

Oversea Warehouse: Some machines can be shipped from overseas warehouses to reduce delivery time and cost.

Custom Packaging Solution:Offer one-stop packaging solution through detailed packaging production need.