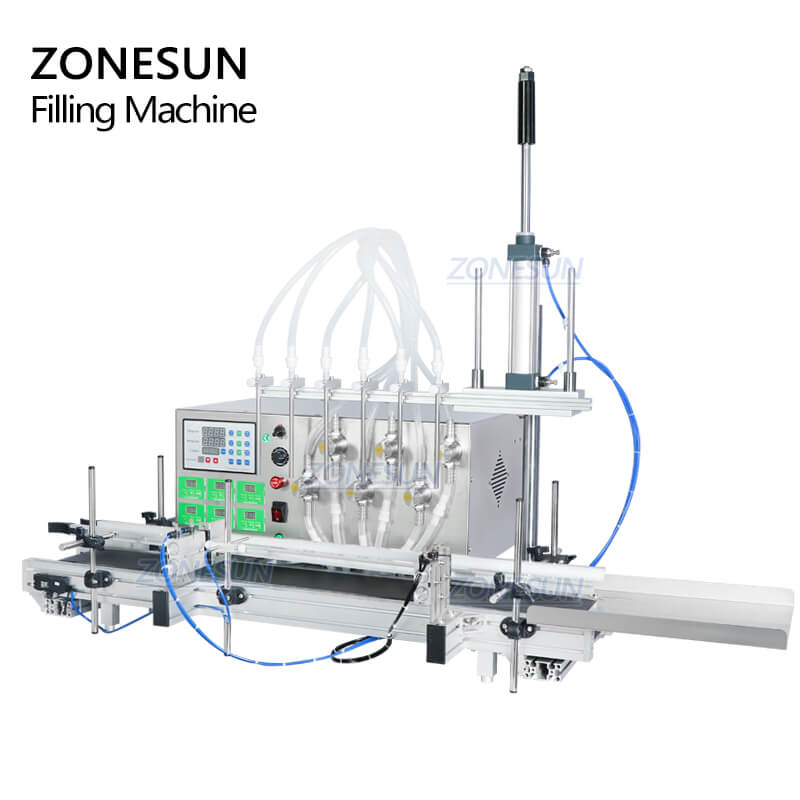

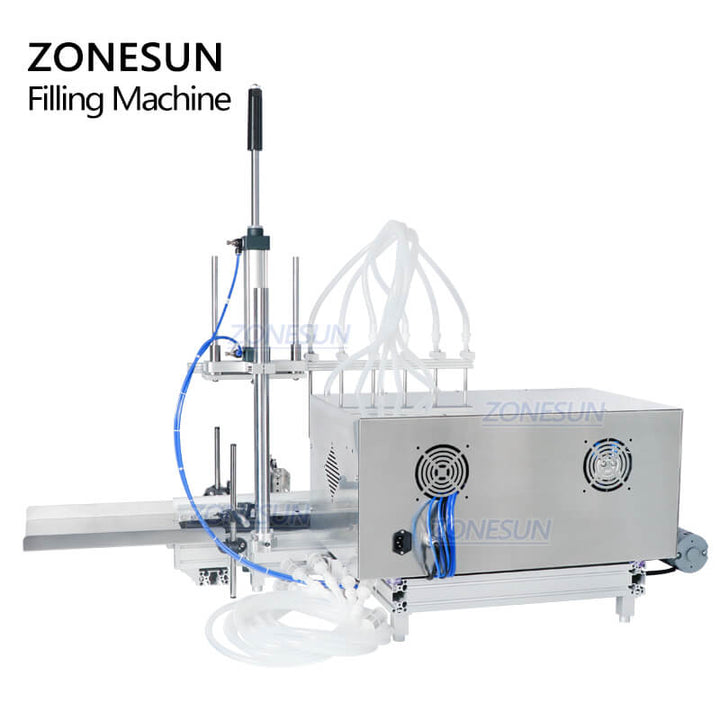

The automatic tabletop filling machine is suitably applied on low viscosity liquid like water,juice,perfume,milk,essential oil etc.This machine is equipped with magnetic pump, it is driven by the force of magnets.It does not have the shaft coming out of the pump casing, hence there is no need for shaft sealing devises such as gland packing or mechanical seals.The liquid will not leaking in this situation.As a result, people working on or near the pump are not exposed to dangers from hazardous, corrosive, flammable or explosive fluids, and other toxic chemicals. In addition, expensive liquids are not wasted.

Parameter

- Machine model: ZS-DTMP6A

- Power supply: 110/220V 50-60 HZ

- Maximum flow velocity: 5500 ml/min (Each nozzle and base on water)

- Working speed: 30-40 bottles/min(based on 50-1000 ml filling volume)

- Air pressure: 0.3-0.4 MPa

- Filling accuracy: ≤±1% (For water)

- Diameter of Filling Nozzle: 6/8 mm

- Delay Range: 0.01-999.9 s

- Count Range: 1-99999 Times

- Filling Volume: 3-1000 ml(220V) 3- 500 ml(110V)

- Size of air compressor connector: OD8 mm

- Bottle height:<220 mm (Can be customized,max height 300 mm)

- Package Size: About 1105*715*435 mm

- Gross weight: About 66 kg

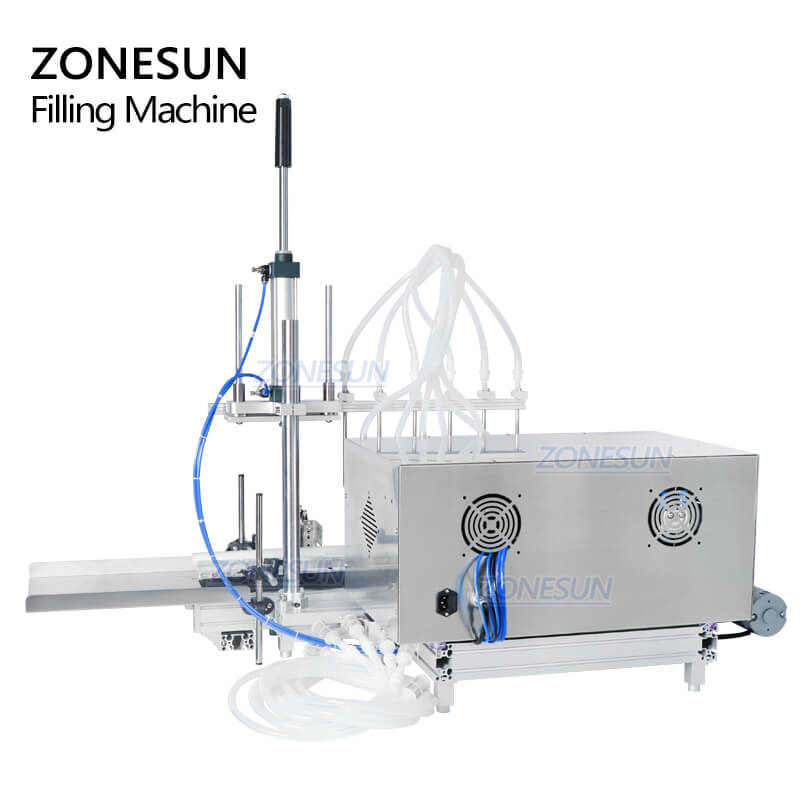

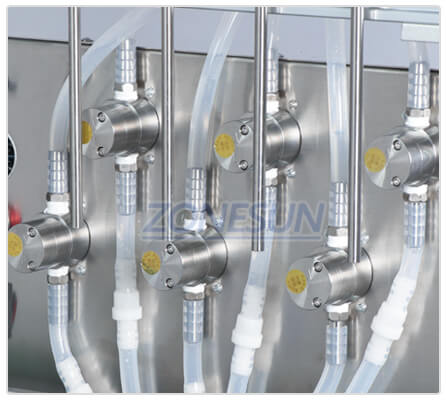

Designed into 6 diving filling nozzle,each nozzle can be controlled separately,it is suitably applied on filling different kinds of liquid at the same time.

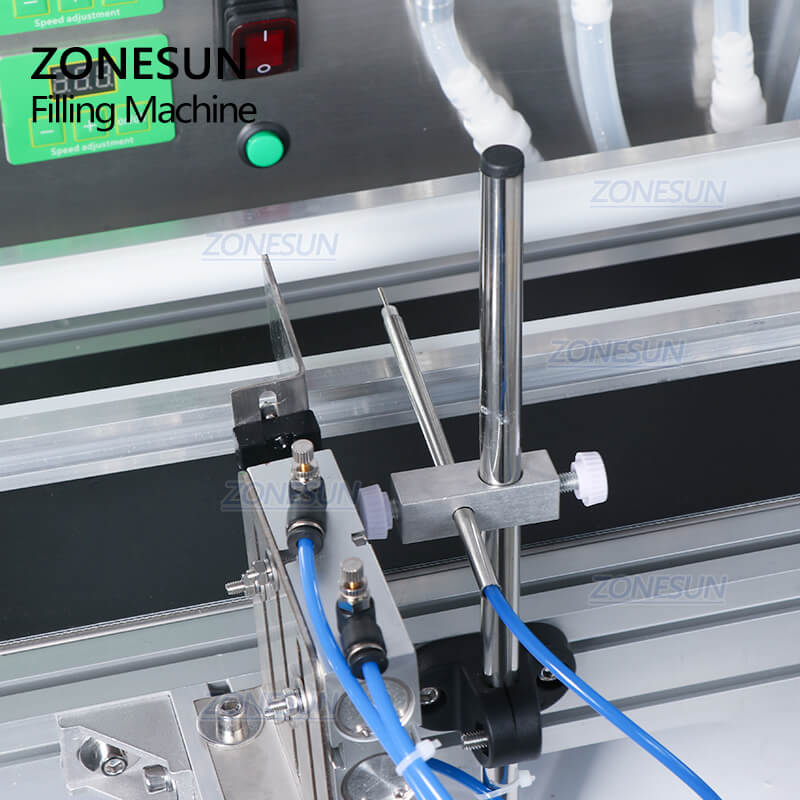

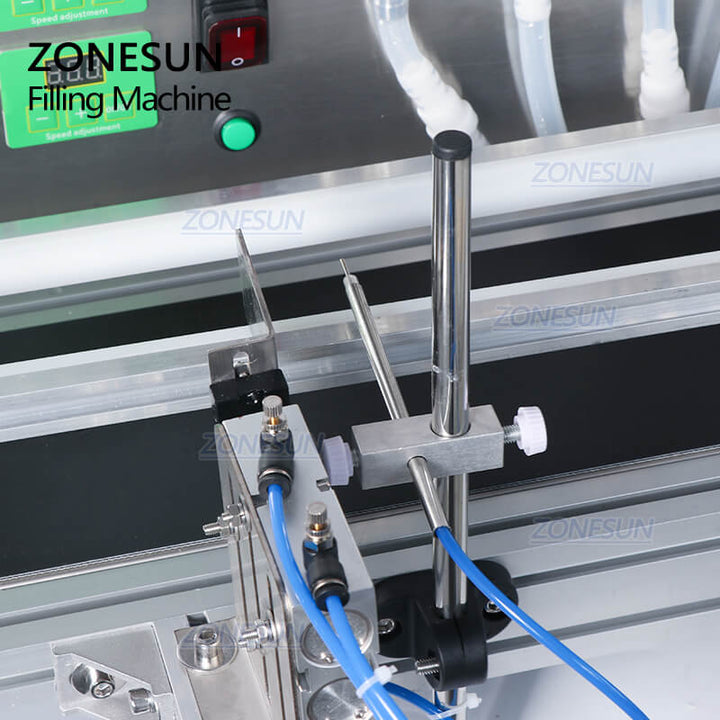

Equipped with an air cylinder to control the diving nozzle,this can ensure the machine will not produce too many bubbles during filling.The lifting distance can be adjusted according to production need.

The high quality magnetic pump is made of 304 stainless steel,food grade stainless steel is more suitable for filling drinks,ensure the production quality.We can also customize the 316 magnetic pump if you need it.

Based on the principle of light transmittance,the electric eye can detect passing by containers accurately and send the signal to the system and control the machine to work.Ensure that there is no bottle will be missed.

It is equipped with high quality conveyor belt to realize automatic filling work,the container will be transported smoothly and stably,reduces production error and save production labor.