Small Changes of Dropper Bottle Capping Machine Improves Essential Oil Packaging Quality

The packaging of essential oils plays an important role in conveying the unique development concept of products. At the same time, in order to ensure the product quality of essential oils during transportation, storage and use, the packaging of essential oils usually has the following two characteristics.

①Using dropper design

The essence is precious, and the concentration of active ingredients is high. Compared with the method of pump head pressing, the dropper design will make it easier to achieve accurate liquid extraction, thereby avoiding wasting essence. A more succinct explanation can also be made on the instructions for use, for example, three drops of essence are used at one time. At the same time, the design of the dropper is similar to the chemical reagent bottle, which can give consumers a more professional and trustworthy feeling.

②Use an amber glass bottle

Glass bottles prevent chemical reactions with the product. At the same time, essential oils cannot be preserved well under the irradiation of ultraviolet rays, so it is necessary to use amber glass bottles to block most of the ultraviolet rays.

In view of the above two characteristics, manufacturers usually face the following three problems in the automated packaging process

①When using a vibrating bowl sorter to achieve traditional automatic cap feeding, the cap with a longer dropper is difficult to accurately fall into the bottle, resulting in production errors

② When the amber bottle passes through the working components (such as the capping component) on the packaging line, the machine does not receive the instruction to perform the capping action

③Some dropper caps are made of metals, and it may scratching dropper caps during automated cap feeding work

Therefore, we made the following two adjustments to the machine, which successfully improved the packaging quality of the product

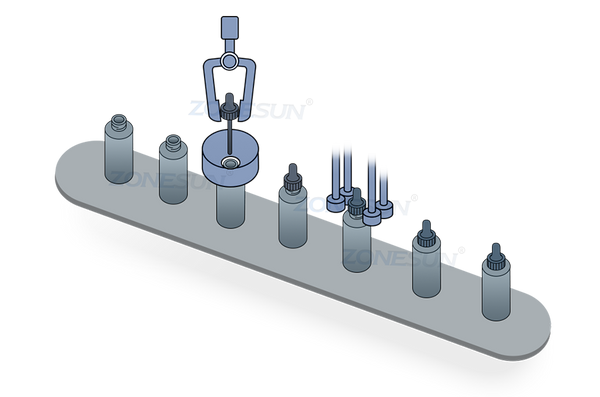

①The machine is equipped with a special working component, which can simulate the human hand to put the cover into bottles. This solve the problem that caps with long droppers cannot be accurately put into the bottle, improves capping accuracy.

② Equipped with a more reliable photoelectric sensor. The working principle of the photoelectric sensor is to project light to the detection area, receive the light passing through the detection area or the light reflected by the detection area, and obtain information about the presence or absence of objects in the detection area or the characteristics of objects based on the amount of light received . Since amber bottles reflect less light, more sensitive and reliable sensors are needed to reduce production errors during automated packaging.

③The cap vibrating bowl sorter can be customized with flock coatings, which can prevent caps from scratching effiectively.

To sum up, when you choose a suitable dropper bottle capping machine for your essential oil products, you may wish to pay attention to whether the machine has the above three characteristics. At the same time, make a correct choice based on your product packaging characteristics and production efficiency.

ZONESUN is the professional packaging machine manufacturer and we have offered more than 5000 packaging solutions for different packaging industries. If you are finding the packaging machine for essential oil or cosmetic products, please send email to sales@zonesuntech.com to get better recommendation.

Leave a comment