Capping machines are used for the application of plastic and metal threaded caps as well as some fitments and some types of corks and plugs. They can be divided into manual capping machine,semi-automatic capping machine and automatic capping machine.

Shop By Caps Type

Are There Multiple Types Of Capping Machine?

Yes, there are multiple types of capping systems, each designed for specific applications, container types and working capacity. We offer below common capping systems used in various industries:

1. Screw Capping Machine

- Application: Used for applying screw caps on bottles or containers.

- Operation: Four rubber wheels or one capping chuck are used to fix and tighten caps when they are placed on the bottles.

They are commonly divided into inline screw capper, rotary screw capper and handheld screw capper.

2. ROPP (Roll-On Pilfer-Proof) Capping Machine

- Application: Commonly used for sealing wine, spirits, and pharmaceuticals.

- Operation: The cap is placed on the bottle, and rollers are used to mold the cap to the neck of the container. These caps often have a tamper-evident seal.

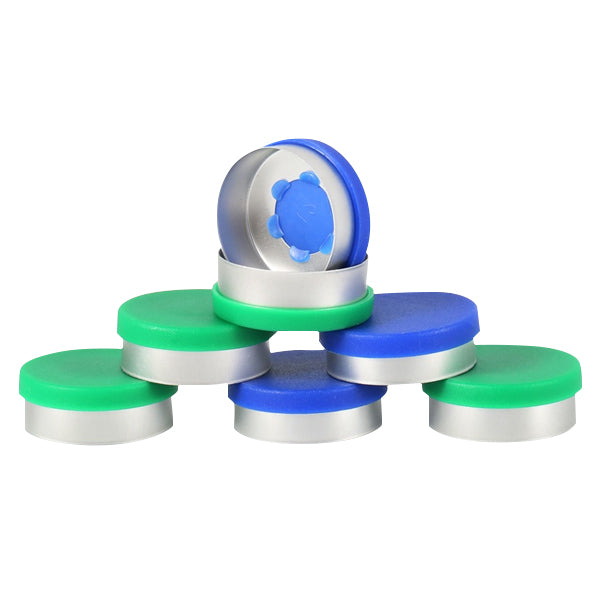

3. Crimp Capping Machine

- Application: Used for containers like vials or bottles with aluminum caps, often seen in pharmaceuticals or perfume.

- Operation: The crimping head consists of a set of crimping jaws (rollers or chuck) designed to fold the metal cap around the neck of the bottle.During capping process, the jaws close around the cap, applying pressure. They rotate or squeeze to fold the edges of the aluminum cap tightly around the bottle's neck, ensuring a secure fit.This is commonly used in vial flip off caps or perfume caps

4. Corking Machine

- Application: Used for sealing bottles with natural wooden corks or T-corks, common in the liquor, beverage and wine industries.

- Types:

① Manual Corking Machines: For small-scale production.

②Semi-Automatic and Automatic Corkers: Used in larger operations for higher efficiency.

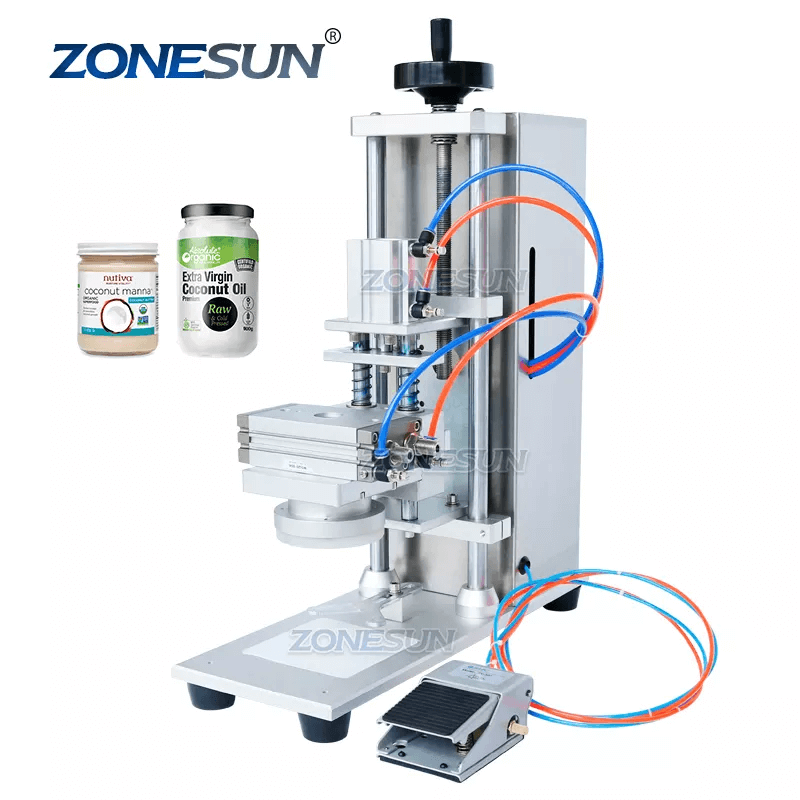

5. Press-On Capping Machine

- Application: Used for caps that simply press onto the container without twisting, such as snap-hinged caps.

- Operation: The caps are applied by pressing down with a machine.

6. Pump and Trigger Capping Machine

- Application: Used for bottles that require a pump or trigger mechanism, such as spray bottles for cleaning supplies or cosmetics.

- Operation: The capping system is designed to attach the pump or trigger assembly securely to the bottle.

7. Vacuum Capping Machine

- Application: Used in food and beverage industries to seal containers under a vacuum, ensuring an airtight seal and extending product shelf life.

- Operation: The cap is applied while the air is evacuated from the container.

8. Spindle Capping Machine

- Application: Used for screw-on caps in high-volume production settings.

- Operation: Containers move through a series of spinning spindles that tighten the caps.

Each capping system is chosen based on factors like container shape, material, production speed, and specific sealing requirements (e.g., tamper-proof, airtight).

What Information Will Need To Be Provided When Customizing a Capping Machine?

When customizing a capping machine, providing detailed information about the requirements and specifications is important.We usually will need below information when customizing a capping machine

1. Type of Container

Container Shape: Provide the shape (round, square, rectangular, etc.) of the bottles or containers to be capped.

Container Size: Specify the dimensions (height, width, and diameter) of the containers.

Neck Size: Provide the exact dimensions of the container’s neck, including the diameter, height, and thread size (if applicable).

Material: Indicate the container’s material (plastic, glass, metal, etc.) as this can affect the capping process.

2. Type of Cap

Cap Style: Define the type of cap (screw cap, snap cap, ROPP cap, crimp cap, cork, pump, or trigger).

Cap Size: Provide the dimensions of the cap, including its diameter and height.

3. Production Speed and Volume

Production Rate: Specify the required production speed, usually in bottles per minute (BPM).

4. Automation Level

Manual, Semi-Automatic, or Fully Automatic: Define the level of automation you need, depending on whether you want operators to manually load containers and caps or if the entire process should be automated.

Conveyor System: Specify if you need a conveyor system integrated with the capping machine for automatic feeding of bottles.

Cap Feeding System: Indicate whether you need an automatic cap feeder (hopper, sorter, or elevator) or if caps will be placed manually.

5. Other Requirements

If there are other special requirements for the machine, please specify, such as whether it needs to support vacuum sealing, or whether it needs to have explosion-proof function, etc.

6. Space Constraints

Available Floor Space: Provide dimensions for the available space where the machine will be installed. This will help in designing a machine that fits within your facility.

Height Restrictions: Include any height limitations in your production area, especially if the machine will be integrated with other equipment like filling machines or conveyors.

7. Power and Air Supply

Electrical Requirements: Specify the voltage and frequency (e.g., 220V, 380V, 50Hz, 60Hz) available in your facility for the machine's power source.

Compressed Air Requirements: If the machine uses pneumatic components, specify the available air pressure and volume capacity in your facility.

8. Integration with Existing Systems

Upstream/Downstream Equipment: If the capping machine needs to integrate with other equipment (e.g., filling machines, labeling machines, packaging systems), provide information on those systems for proper synchronization.