ZONESUN ZS-CQ2 Semi-Automatic 25.4mm Air Freshener Sunscreen Spray Aerosol Metal Cans Gas Filling Machine

Regular price

$2,199.00 USD

$2,199.00 USD

Regular price

Sale price

$2,199.00 USD

$2,199.00 USD

Save $-2,199 USD

/

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

- Local Service Location (Romania /Serbia /Kazakhstan/Mexico/Indonesia)

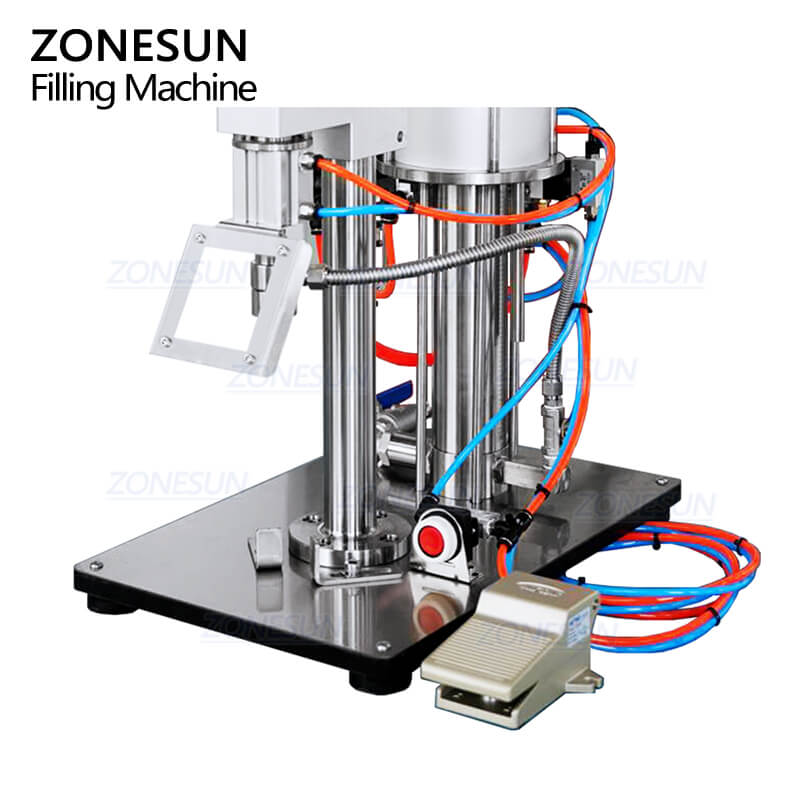

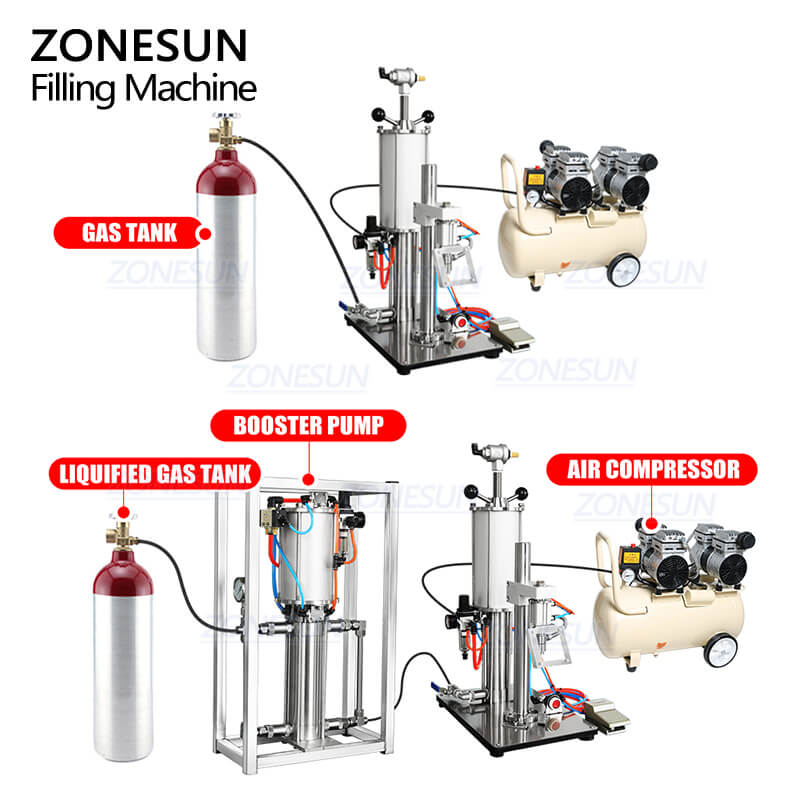

This gas filling machine efficiently fills aerosol cans with various propellants, including fluorocarbon propane-butane, dimethyl ether, carbon dioxide, nitrogen, oxygen, compressed air, and 134 A. It requires an air compressor and gas tank for operation and features a pneumatic foot pedal for easy activation. The filling volume is adjustable via the rotating handle on top, with reference scale values for accuracy. An emergency stop button enhances safety. A protective cover in front of the filling head prevents accidental spills. For liquefied gas filling, an additional booster pump is required (sold separately).

Parameter

- Model: ZS-CQ2

- Filling Capacity: 30-500 ml

- Filling Accuracy: ≤±1%

- Production Capacity: 1200-1500 cans/hour

- Applicable Valve: 1 inch(25.4 mm)

- Working Pressure: 0.5-1.0 MPa

- Maximum Air Consumption: 0.5 m³/min

- Product Size: 50*30*75 cm

- Weight: 55 kg

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

This machine can filling a wide range of propellants commonly used in aerosol cans, including: fluorocarbon propane-butane gas, dimethyl ether, carbon dioxide, nitrogen, oxygen, compressed air, and 134A

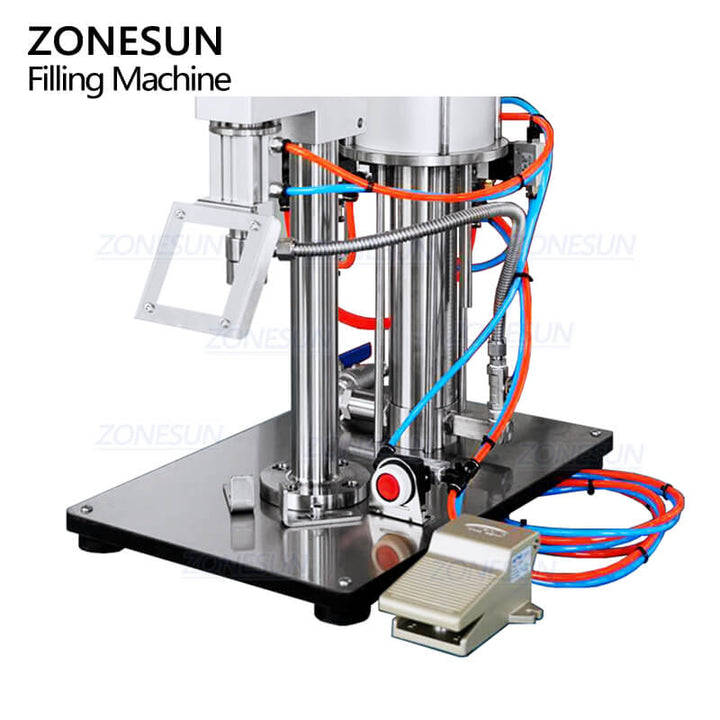

A protective cover is installed in front of the filling head to prevent accidental gas spills and protect the operator from potential exposure to the propellant. This enhances safety and ensures a clean working environment.

The machine features a convenient pneumatic foot pedal that allows for hands-free activation of the filling process This is particularly useful for repetitive filling tasks, as it frees up the operator's hands to handle the aerosol cans.

If you intend to fill aerosol cans with liquefied gas an additional booster pump is required. This pump increases the pressure of the liquefied gas, allowing it to be efficiently transferred into the aerosol cans. The booster pump is sold separately and should be chosen based on the specific type of liquefied gas being used.

Related Products

No reviews