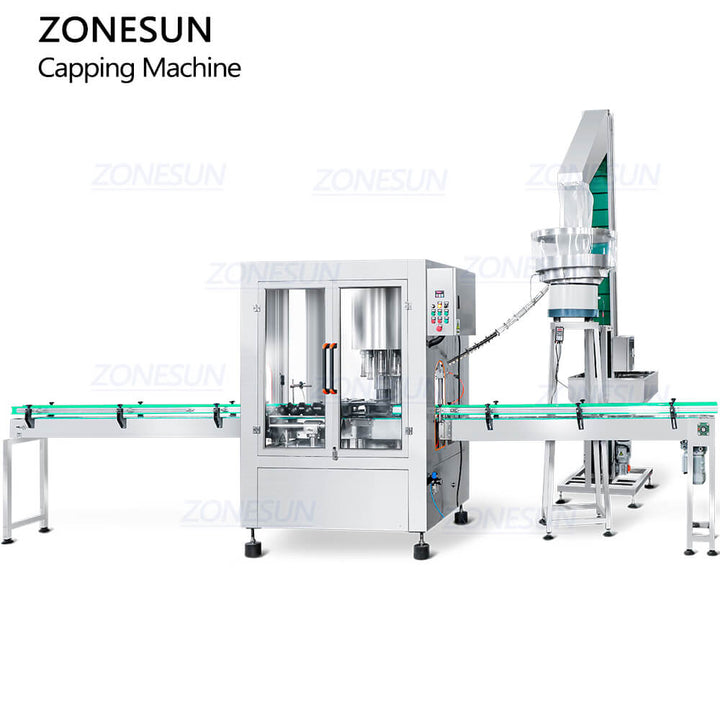

This high speed monoblock corking machine integrates multiple functions into a single unit, typically combining various steps including cork feeding, cork pressing into one streamlined operation.This corking machine can handle a large volume of bottles per hour, significantly increasing production efficiency for wineries or bottling facilities

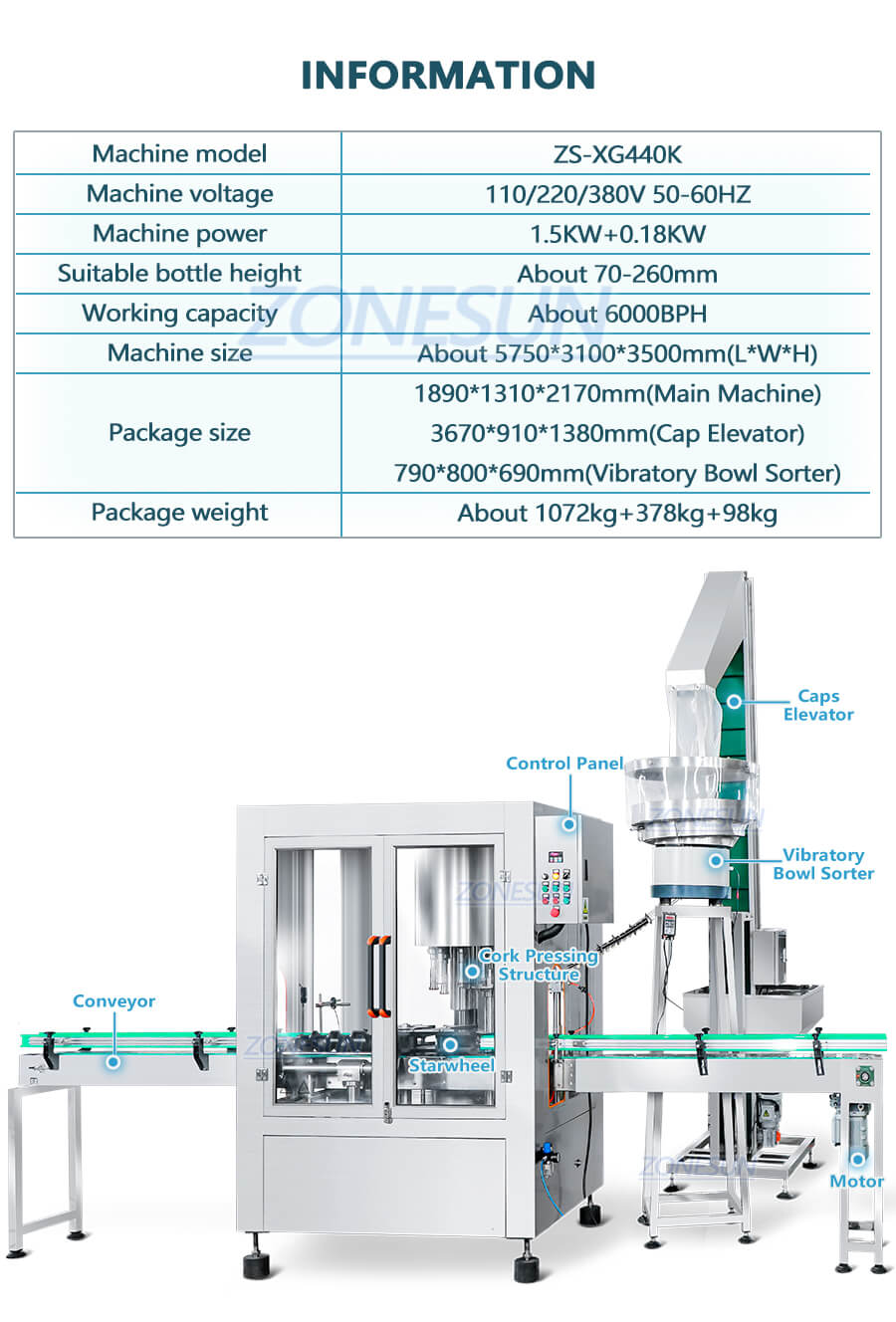

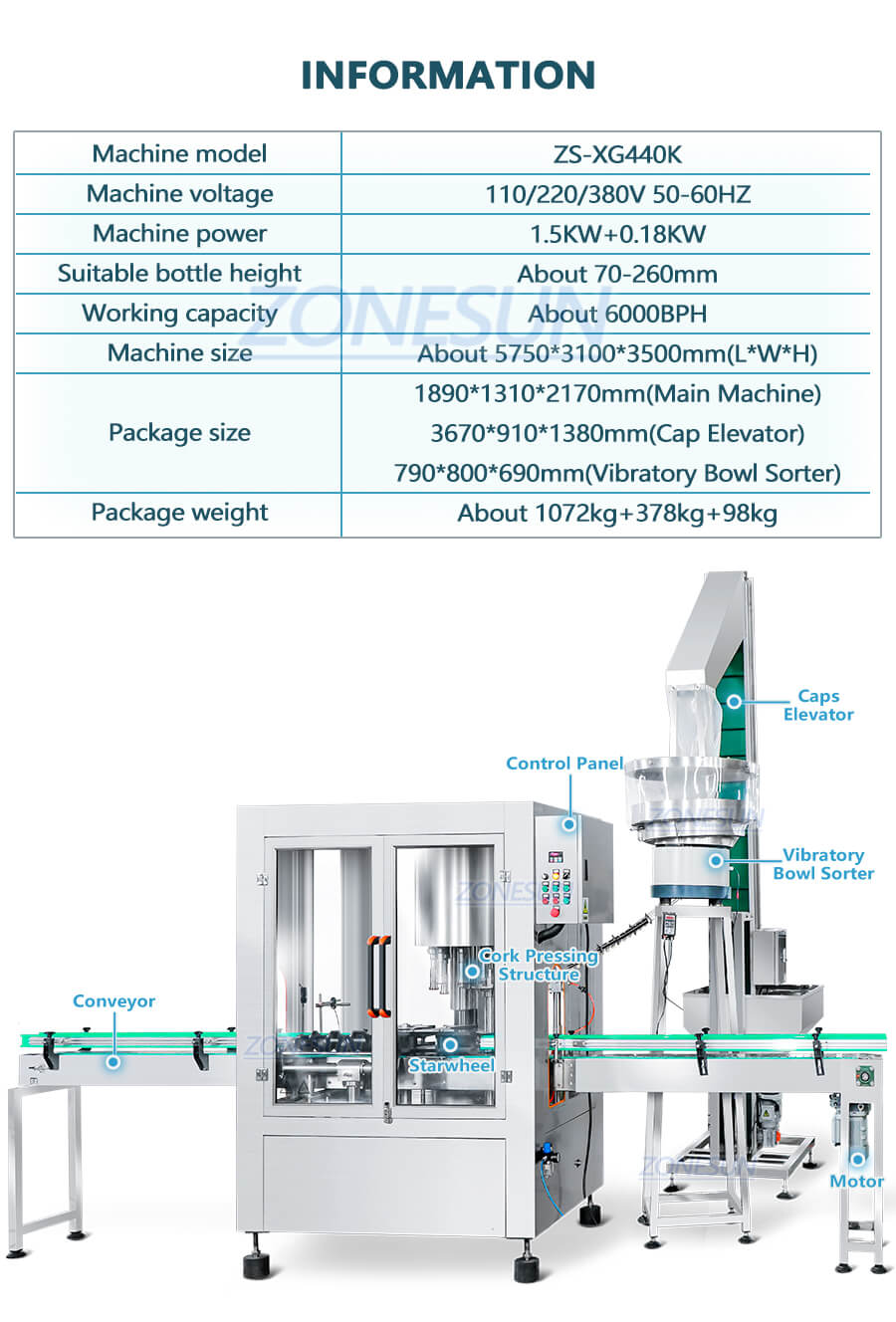

Parameter

- Machine model: ZS-XG440K

- Machine voltage: 110/220/380V 50-60HZ

- Machine power: 1.5 KW+0.18 KW

- Suitable bottle height: About 70-260 mm

- Working capacity: About 6000 BPH

- Machine size: About 5750*3100*3500 mm(L*W*H)

- Package size: About 1890*1310*2170 mm(Main Machine) 3670*910*1380mm (Cap Elevator) 790*800*690mm (Vibratory Bowl Sorter)

- Package weight: About 1072 kg+378 kg+98 kg

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

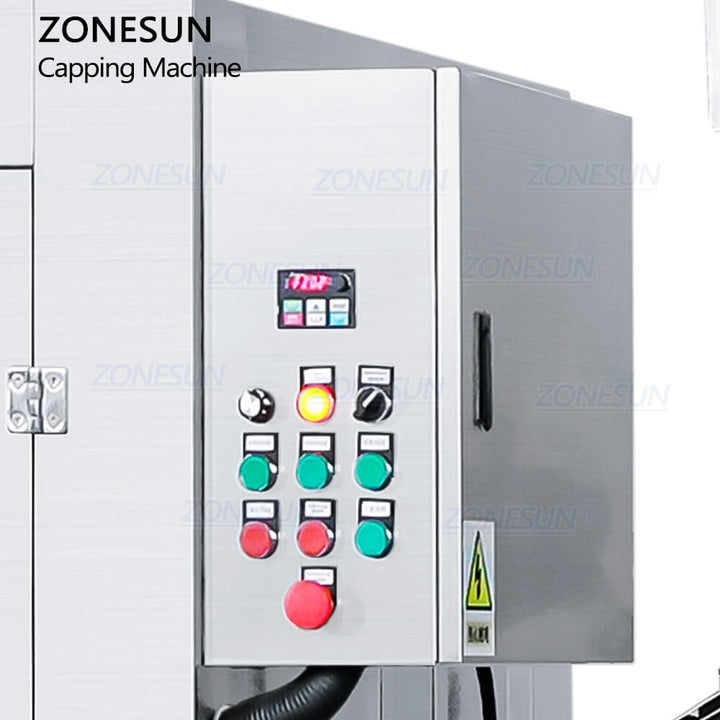

Button control panels are intuitive and easy to use, operators can simply press buttons to initiate specific functions or commands, reducing the need for extensive training.

This machine is equipped with caps elevator and vibratory bowl sorter. The cap elevator can supply corks to the vibratory in time and the vibratory bowl sorter can make cork be in order, this improves working speed and reduce working error.

Starwheel is customized according to bottle diameter, it can ensure bottle can be conveyed smoothly and will not fall down during transporting.Feed screws ensure precise positioning and spacing of products as bottles move along the production line.

Electric eye will detect passing by bottles and control machine to start the cork pressing work automatically, it saves working labor and reduce production error.

The cork can be supplied to the starwheel through the guide rail in advance.This machine has 8 cork pressing heads, bottles will be corked during the rotation process.These ensures working capacity, this corking machine is suitable for large scale production.