This tank is an essential part of the beer brewing process, where yeast converts the sugars in the wort into alcohol and carbon dioxide. It is typically made of stainless steel and is designed to be airtight and temperature-controlled. The Fermenting Tank for Beer is designed to be easy to clean and maintain, with a variety of features that make the brewing process more efficient and effective. These may include temperature sensors, pressure gauges, and other controls that allow brewers to monitor and adjust the fermentation process as needed. Cylindrical conical fermentation tanks are mostly used for fermenting beer. Here, the yeast can settle in the cone at the end of fermentation and be easily separated from the young beer for clean phase separation during yeast harvesting.

Parameter

- Model: ZS-NJJ01 Fermentation Tank

- Rated Power: 235W

- Power supply: 220V 50-60Hz

- Capacity: 34L/65L/120L/200L or custom size

- Temperature Range: Mini.: below zero (ltis recommended to set it at 4-5°C) Max.: equal to room temperature

- Machine Size: 440*580*1200 mm(34L)

- N.W./G.W.: Approx.34 kg/55 kg

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

TEMPERATURE CONTROLLER

Automatically adjusts and maintains the desired fermentation temperature, improving efficiency and simplifying the brewing process

FILLING NOZZLE

Designed to easily and efficiently fill bottles or kegs, minimizing spillage and ensuring clean transfer of beer.

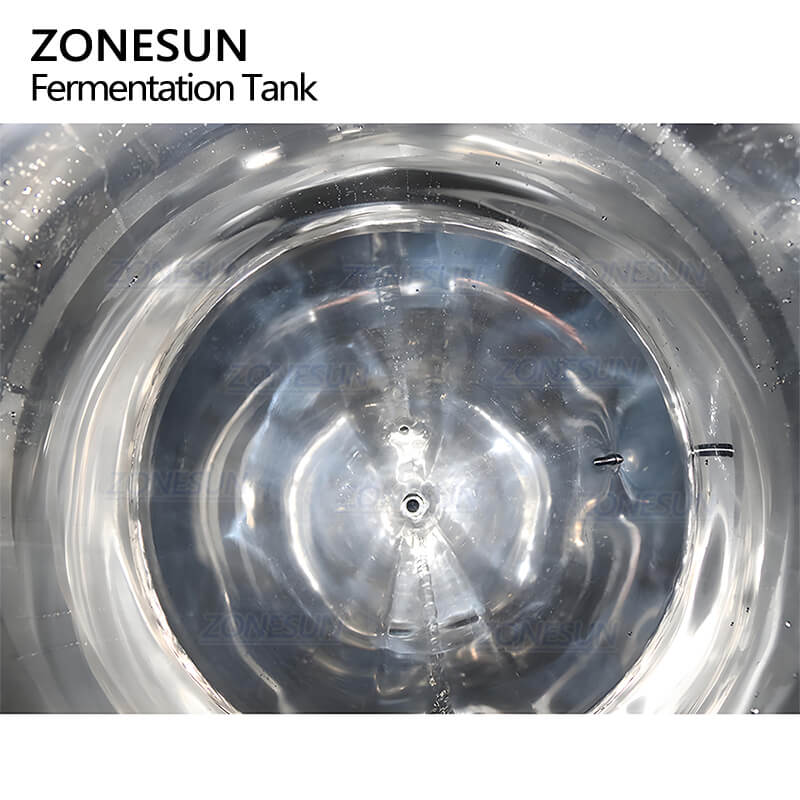

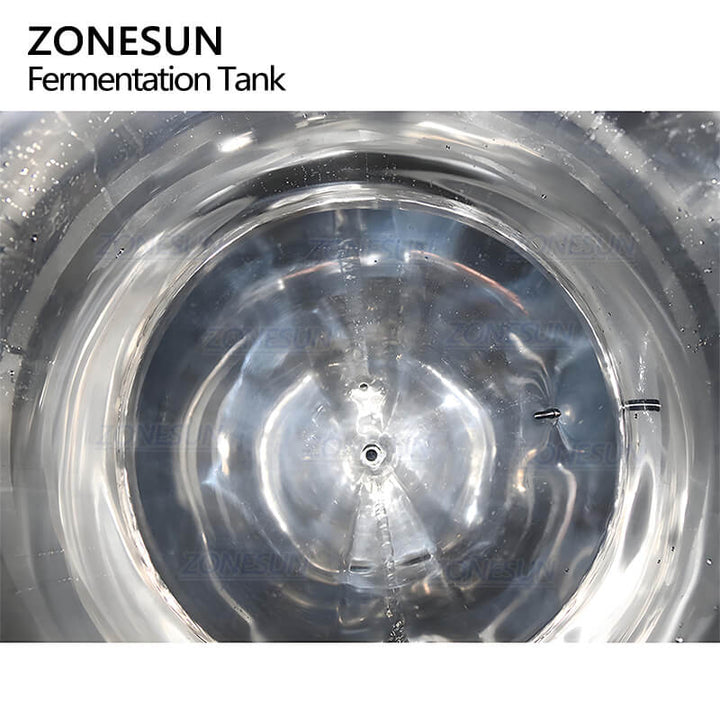

MIRROR POLISHED LINING

Smooth polished surface allows for easy cleaning and maintenance,reducing the risk of contamination and improving hygiene.

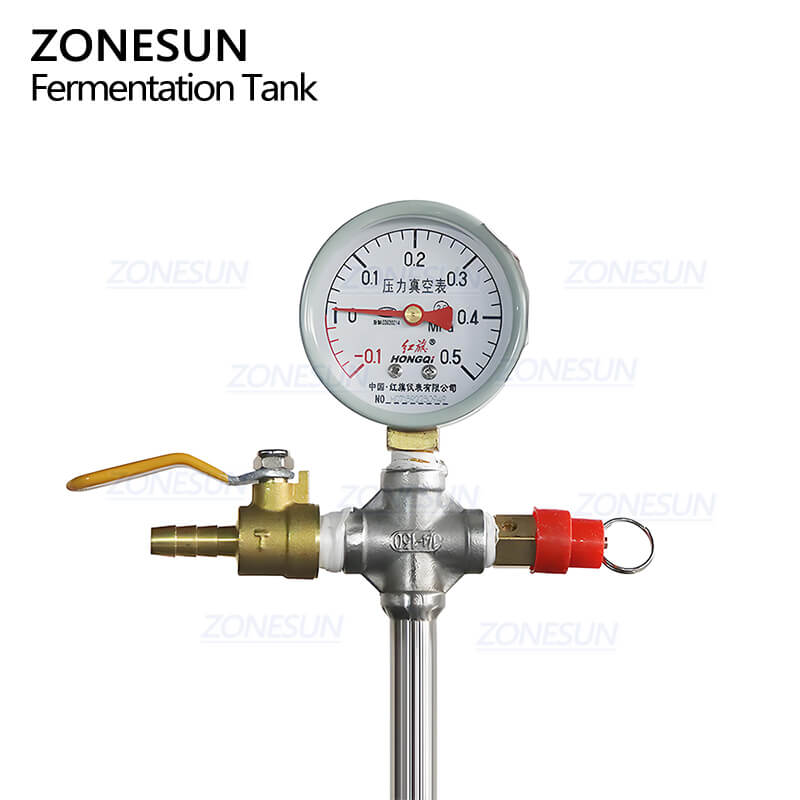

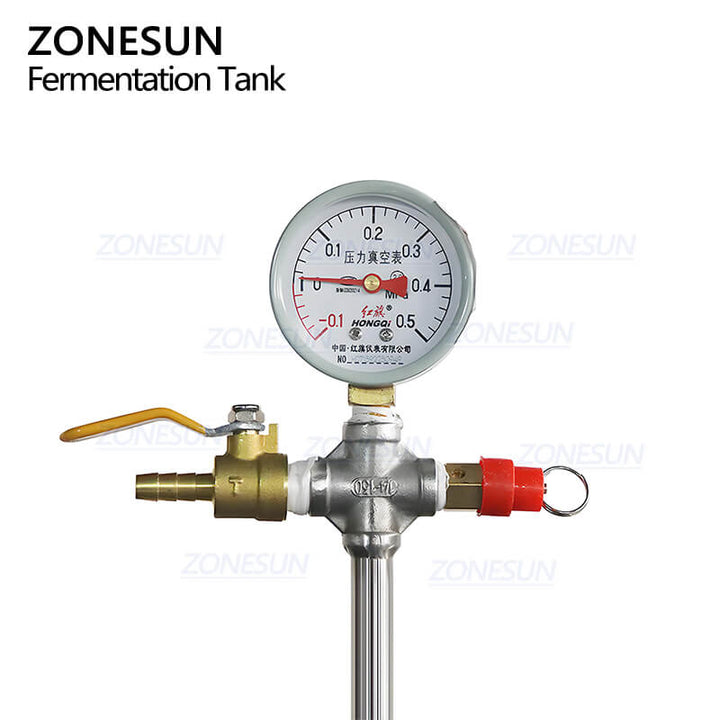

PRESSURE GAUGE

Provides real-time monitoring of internal pressure, ensuring safe and efficient fermentation while allowing for quick adjustments as needed.

UNIVERSAL WHEEL

Allows for easy mobility and convenient repositioning of tanks within the brewery.