This filling line is consist of tracking filling machine, servo capping machine and bottle turntable machine for packaging different shapes of bottles like liquid soap, shampoo, body lotion etc.

Tracking Filling Machine Parameters

- Machine model: ZS-SV4X

- Voltage: 110/220V 50-60HZ

- Machine power: 2KW

- Filling range: 5-100 ml/10-300 ml/50-500 ml/100-1000 ml

- Filling pump: Piston Pump

- Bottle height: 40-250 mm

- Bottle diameter: 30-100 mm

- Working speed: 30-60 bottles/min

- Package size: About 2210*1260*2220 mm

- Package weight: About 950 kg

Servo Capping Machine Parameters

- Machine model: ZS-XG440S

- Voltage: 110/220V 50-60HZ

- Machine power: About 2.8 KW

- Suitable bottle size: H=50-300 mm φ=30-120 mm

- Suitable cap size: φ=20-60 mm

- Working speed: About 30-100 bottles/min

- Machine size: About 2000*750*1650 mm

- Machine weight: About 300 kg

Bottle Turntable Machine Parameters

- Machine model: ZS-SP800S

- Bottle specifications: Square bottle/round bottle

- Conveying speed: 0-20 revolutions per minute(adjustable)

- Voltage: 220V 50Hz (110V can be customized)

- Power supply: 200 W

- Turntable diameter: 800 mm Available

- Dimensions: About 550*550*990 mm

- Package size: About 1050*1000*1130 mm

- Net weight/Gross weight: About 93/120 kg

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

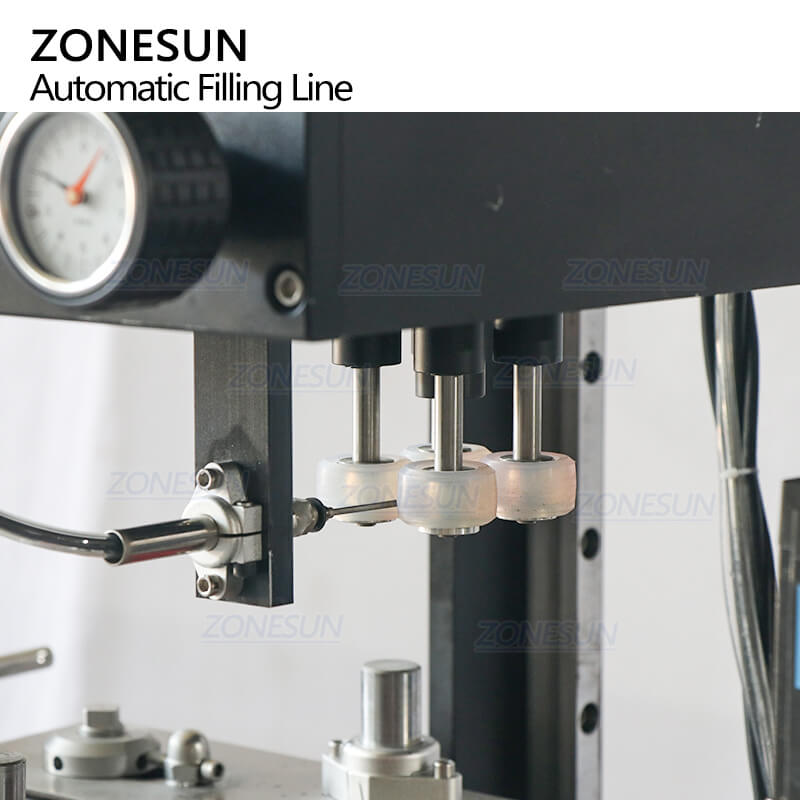

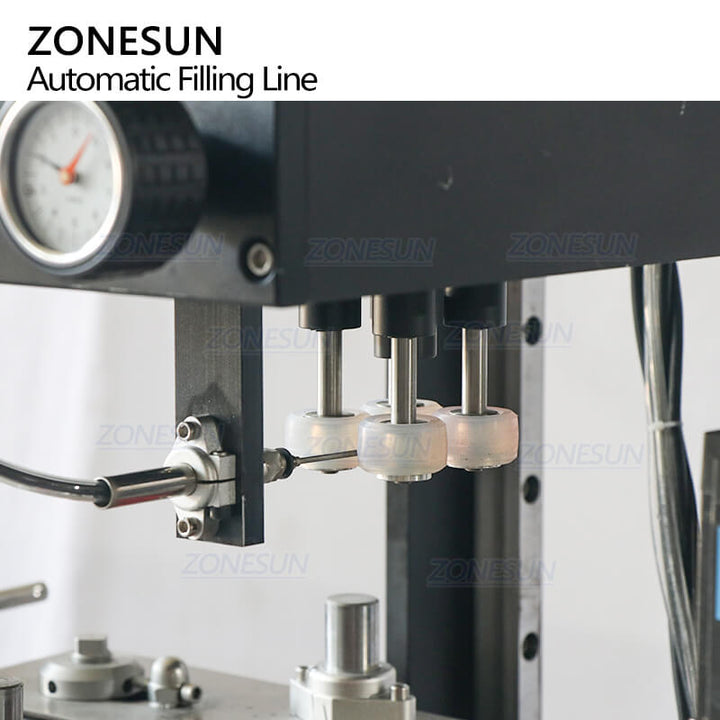

Tracking Filling Nozzle

Multi filling nozzles are customizable, nozzles will follow bottles during filling to improve filling accuracy.

Material Feeding System

Using diaphragm pump to supply filling material in time, saves time and labor.

Electric Eye

It can detect passing by bottles to realize automated production

Bottle Separating Wheel

These can adjust the distance between bottles and bottles, ensure the smooth filling work.

Servo Capping

Servo motor control capping work to improves working accuracy, it suits bottles with screw-on caps.

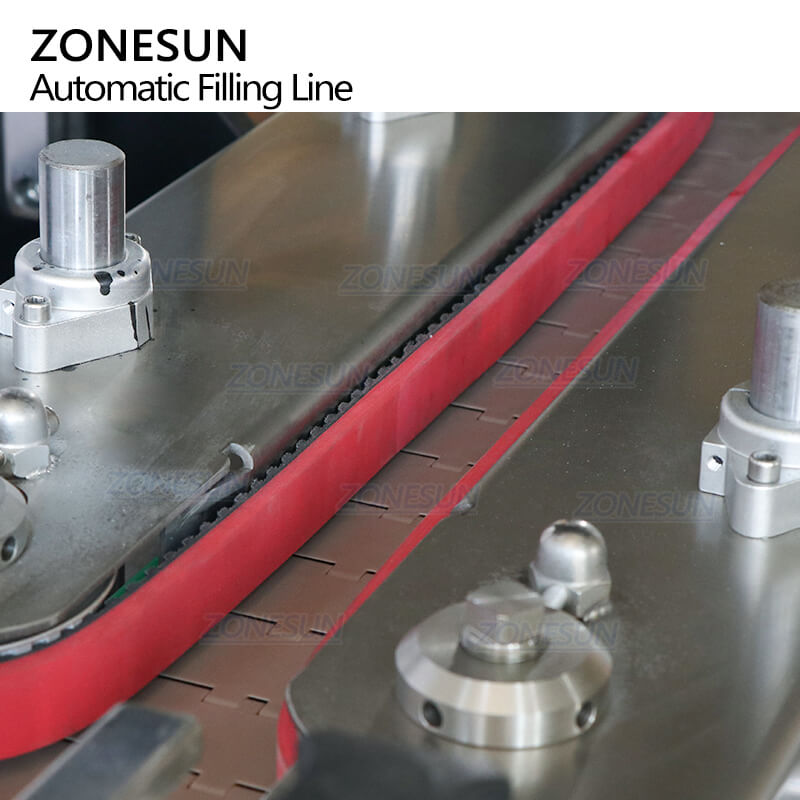

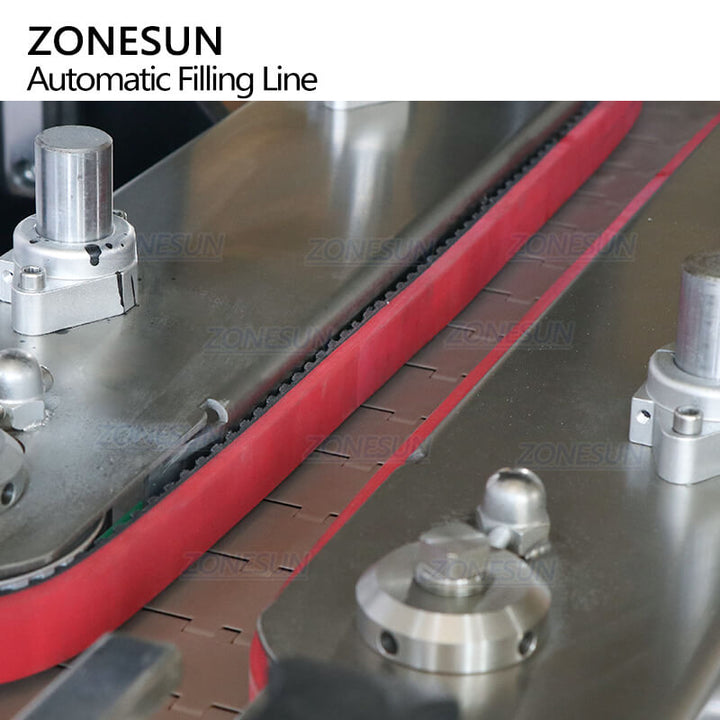

Guiding Conveyor

Prevent bottles from falling down during capping work, it is adjustable based on production need.

Bottle Turntable Machine

Size of bottle turntable machine is customizable based on production need, can integrate with filling, capping or labeling machine.