This is a spout pouch packaging machine with automatic filling and sealing functions. It features 2 filling heads and a rotary worktable design, making it compact and space-saving. All parts in contact with the product are made of food-grade 316L stainless steel, ensuring safety and hygiene. Ideal for ready-to-drink beverages, such as juice, jam, and liquid jelly.

Parameter

- Machine Model: ZS-AFC12

- Voltage: 220V/110V 50-60Hz

- Power: 3kW

- Filling Range: 10-1000 ml(Can be customized)

- Production Capacity: About 1200-1500 BPH (based on filling volume)

- Filling Accuracy: ±1%

- Hopper Capacity: 40L(Can be customized)

- Suitable Cap Diameter: Can be customized

- Suitable Pouch Size: Can be customized

- Air Pressure: 0.5-0.7 MPa

- Air Consumption: 0.7m³/min

- Machine Weight: About 1000kg

- Machine Size: About 3150*1850*2300mm(L*W*H)

Equipped with Siemens swing arm control panel, machine operation and debugging will be more convenient. PLC touch screen shows working data clearly and customizable interface can be customized as needed.

The pouch feeding structure can help to convey pouch to the rotary table in time, it saves production error. We also offer customized tools helping you supply spout pouch faster.

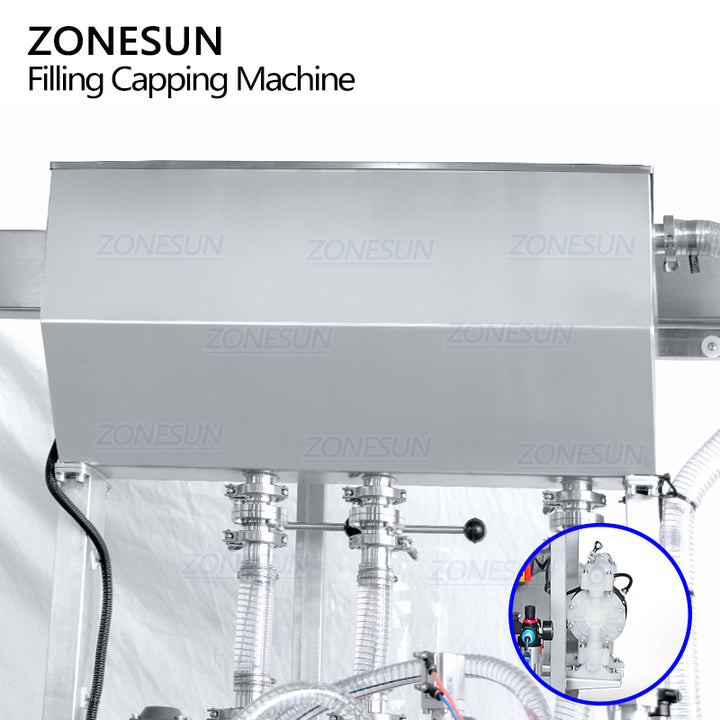

The quantity of filling nozzles can be customized according to production need. Pneumatic filling nozzle is powerful when filling thicker liquid or paste.The filling work is controlled by servo motor piston pump, setting filling volume by control panel directly simplifies machine operation.

The vibrating bowl sorting machine is designed for making pouch caps be in order and can be conveyed smoothly to the next production process.It is customized according to cap size.

The capping structure is controlled by the servo motor, capping torsion can be adjusted according to production need, this ensures the consistency of the capping work.

Equipped with feeding pump, which can feed filling material in time once it is detected that material in hopper is not enough. There is a discharge valve, which can help you discharge left filling material faster after filling work.Mixing and heating function can be customized as needed.

Designed with conveyor, it can transport finished products to the next working process, saves working labor and improves working capacity.