This small automatic capping machine is equipped with vibratory bowl sorter, which can make caps be in order before capping work. What is special is the design of the structure that grabs the lid. It can imitate human hand grasping the cover. This machine is widely used in food, daily chemical and cosmetic industries.

Parameter

- Machine Model: ZS-XG1870R

- Working Voltage: AC220V/110V 50-60HZ

- Bottle Height: 60-270 mm

- Bottle Caps Diameter : 18-70 mm

- Working Speed: 20-40 bottles/minute(depending on bottle and caps)

- Working Pressure: 0.4-0.6 MPa

- Conveyor Length: 1117 mm

- Size of Air Compressor Connector : OD 8 mm

- Package Size: About 1150*640*1110 mm

- Package Weight: About 112 kg

*Specifications are for reference only and may vary by your product. Please confirm with us if required

The touch screen control panel can show working parameter clearly, the visual working data improves working accuracy and reduce working error. Different kinds of operation language can be customized as production need.

The caps vibrating machine will make bottle caps be in order and make the capping work easier and more accurately. The size of vibratory bowl sorter should be customized according to cap size.

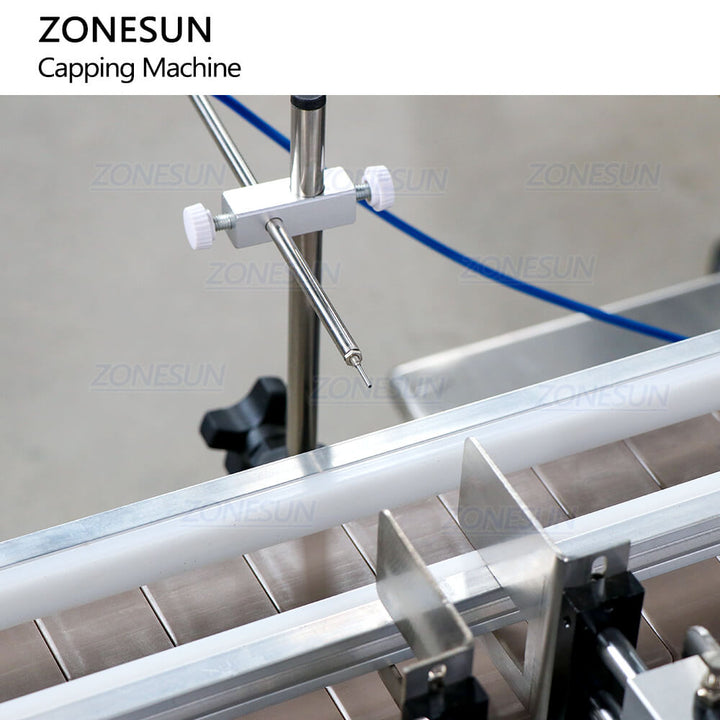

The cap grabbing structure can imitate human hand to grab bottle caps and put it on bottles, this can prevent from scratching bottle caps and improves working accuracy.

This machine tighten bottle caps by four rubber wheels, this kind of capping method is suitable for most of caps with screw threads like spray bottles, pump head bottles, dropper bottles.

The electric eye is used to detect passing by bottles and send signal to the system to control the machine to work automatically. It realized automated production.

Chain conveyor belt has large weight capacity, it will transport bottles smoothly and stably.This is good for improving working speed.