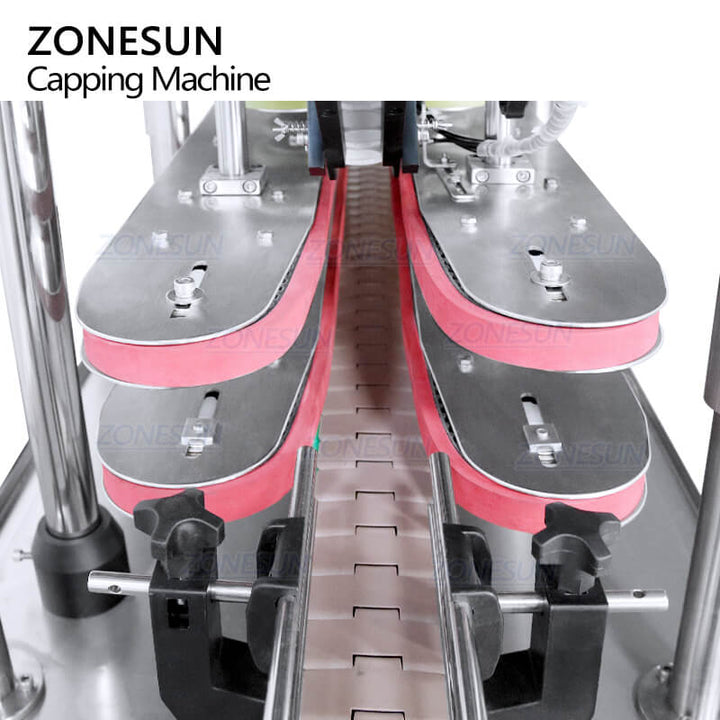

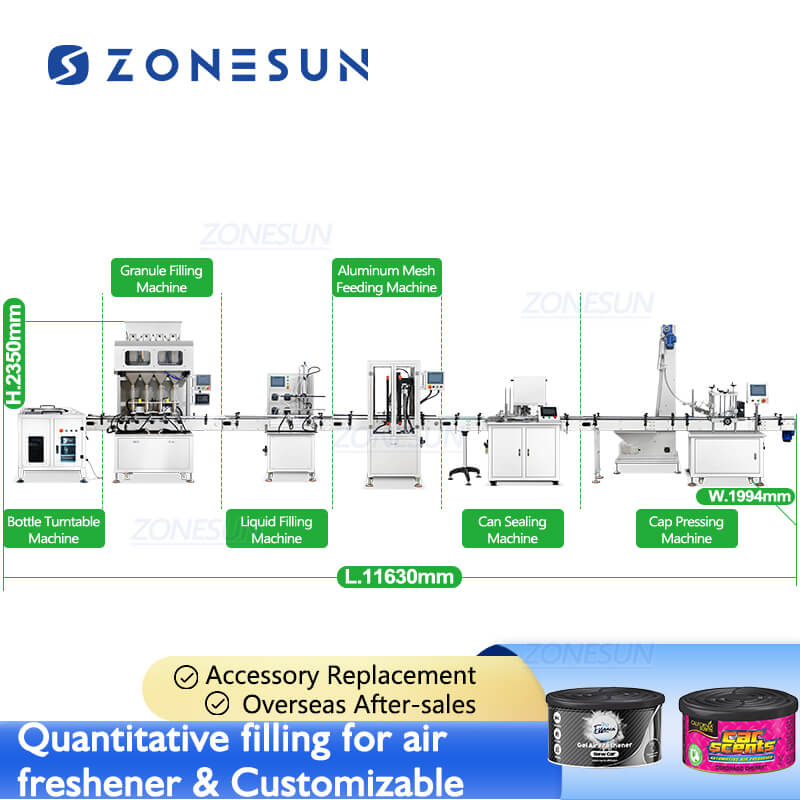

This bottle capping machine is equipped with cap sorting machine, which has lower noise and faster working speed when compared with the vibrating bowl sorting machine. The capping structure is consist of multiple sets of rubber capping wheels, this makes several bottles can be tightened at the same time. It is suitable for packaging screw-on caps in food, beverage, cosmetics and dailyt chemical industries.

Parameter

- Machine Model: ZS-FXZ101

- Voltage: 110/220V 50-60HZ 2KW

- Working Speed: ≤8000 bottles/hour(based on product size)

- Bottle Diameter: About Φ35-96 mm

- Bottle Height: About 80-230 mm

- Bottle Caps Diameter: About Φ12-50 mm

- Bottle Caps Height: About 15-40 mm

- Air Pressure: 0.5-0.7 MPa

- Machine Size(L*W*H): 2000*1000*2400 mm(Capper)+2420*500*2600mm(Cap feeding elevator)

- Machine weight: About 650 kg (Capper)

*Specifications are for reference only and may vary by your product. Please confirm with us if required

Unlike the vibrating bowl sorter, the cap sorting unit uses electricity to keep the bottom and the wall of the cap sorting unit l in rotation, arrange the caps in order and transport them to the guide rail. Equipped with electric eyes to identify and remove caps that are not properly aligned, this unit operates with less noise and works more efficiently

The capping structure is consist of serval sets of rubber capping wheels, these can tighten several bottles at the same time, it is suitable for screw-on caps and has faster working speed.

The bottle guiding conveyor can be adjusted according to bottle diameter.This can prevent oval bottles from falling down during capping process.

Equipped with cap feeding elevator, this can ensure bottle caps can be supplied in time.It saves working labor and can improve working capacity greatly.

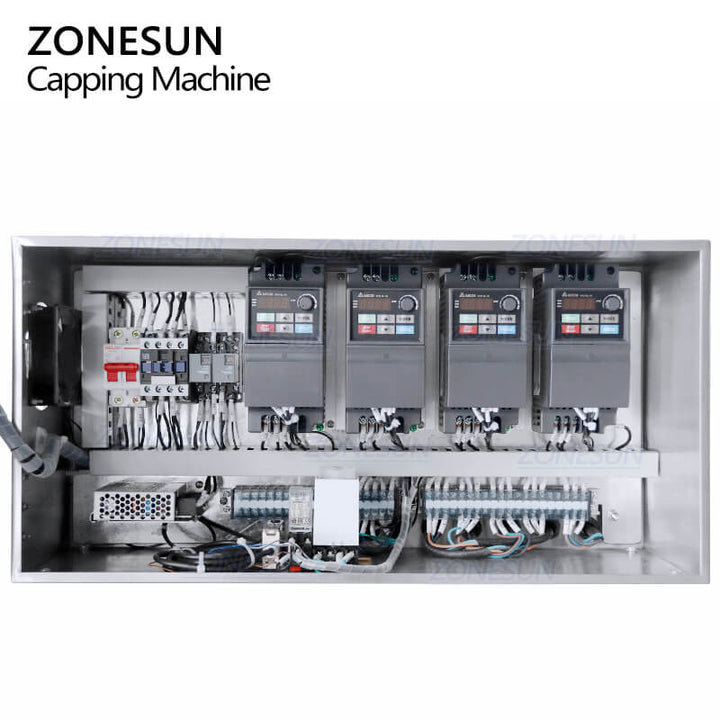

The orderly circuit in a machine can help improve performance, reduce errors, make maintenance and repairs easier, and allow for a more compact design