High speed CCD camera scans objects that fall from vibrating chutes to obtain full projection images through optimized algorithm,machine will count number of falling objects so as to realize the batch counting and packaging. Utilizing advanced visual counting technology (CCD) for exceptional accuracy (±0.003), it ensures precise quantity control. Switching between materials and bag sizes is quick and easy (under 5 and 2 minutes respectively), minimizing downtime.

Parameter

- Model: ZS-JSP20

- Voltage: 220V

- Packing speed: 5-20 bags/min

- Bag type: Back Seal

- Weight: 280 kg

- Dimension: (L)2200*(W)1580*(H)1450 mm

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

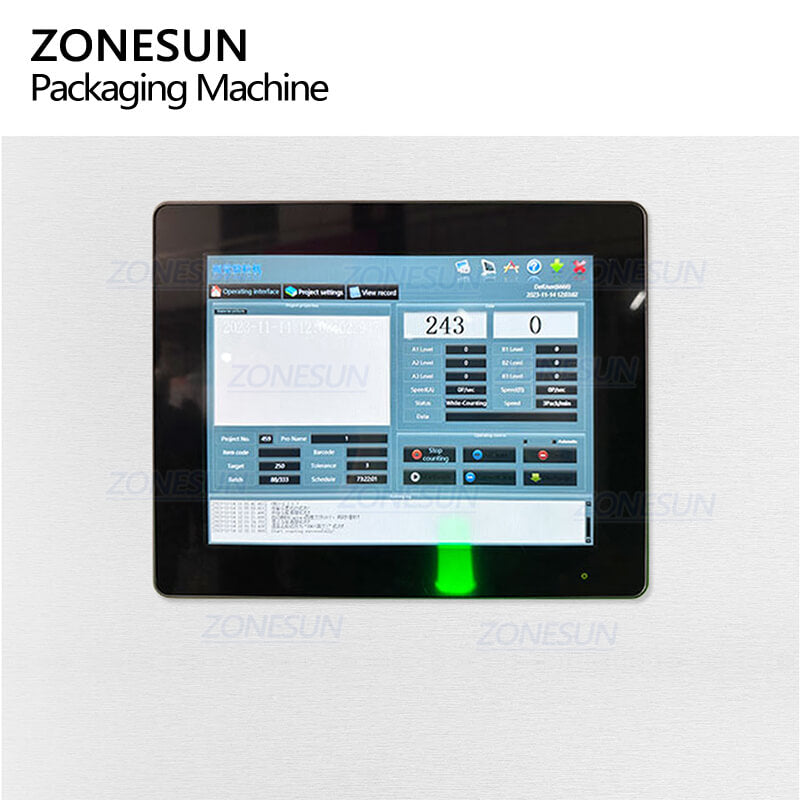

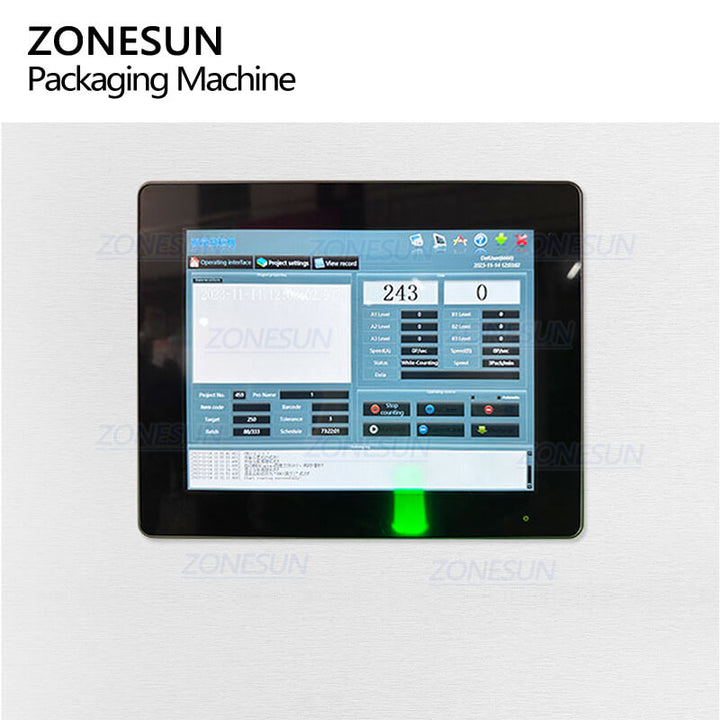

CONTROL PANEL

Simply set the required parameters (filling volume, bag length, etc.) in the displayable setting unit. The control system automatically optimizes and matches the coordination of each action to achieve the best packaging speed.

VISUAL COUNTING

Counting with vision, high accuracy, and the accuracy error is controlled within 5/10,000.Adopting HMl industrial control computer, it is easy to operate. It can save 100 kinds of product information and switch production randomly.

INTELLIGENT SWITCHING

Support one machine to pack multiple products of different sizes. When changing varieties, there is a one-key clearing function. The emptying is manually detected and replaced with new materials. The overall time can be controlled within 5 minutes.

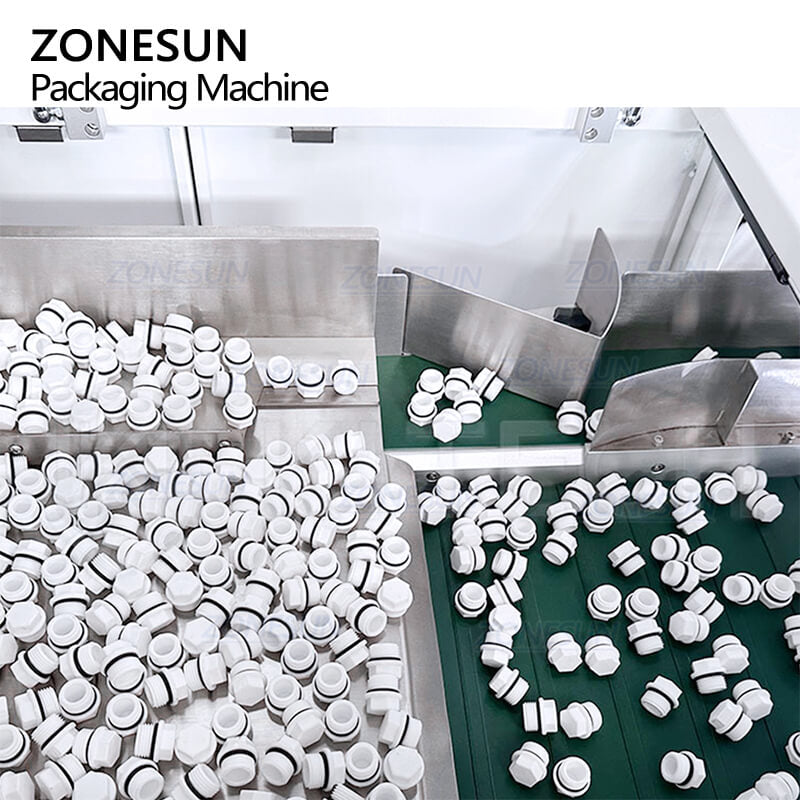

VIBRATING CONVEYOR

The material is transported from the hopper to the counting area smoothly and consistently, ensuring reliable flow and preventing blockage, thereby improving overall efficiency.

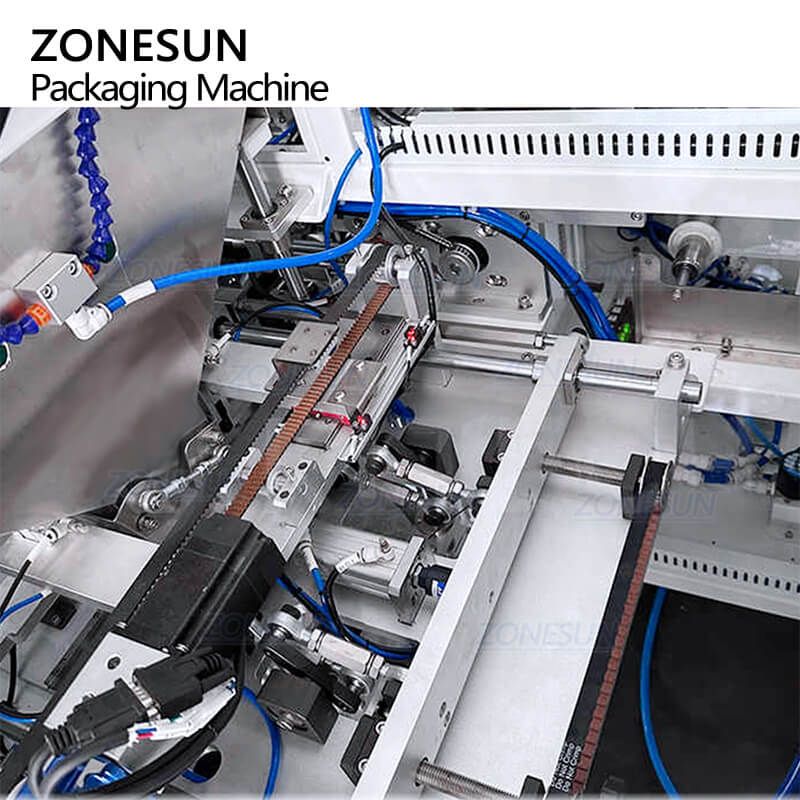

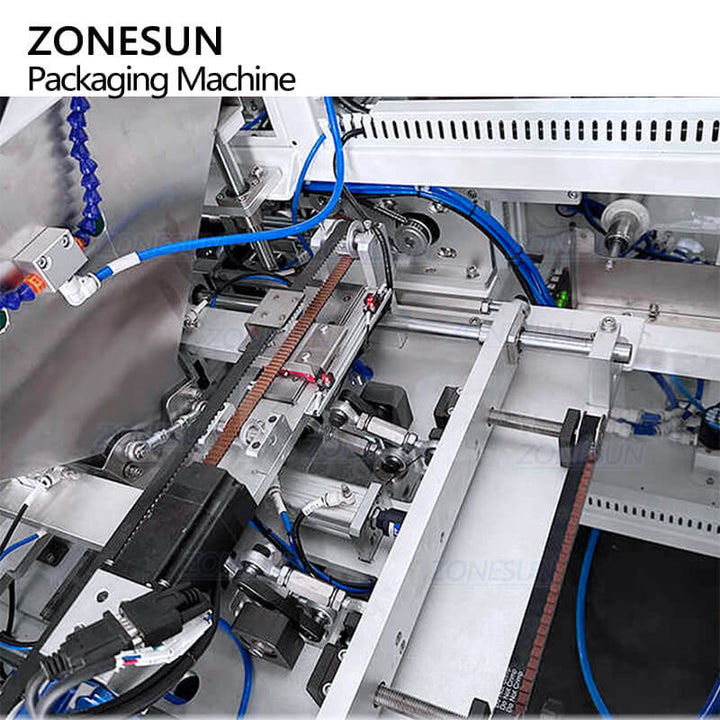

PACKAGING HOST

The core component of the machine, integrating counting packaging and labeling functions, provides a simplified solution for automated packaging processes and improves the productivity of manufacturing operations.