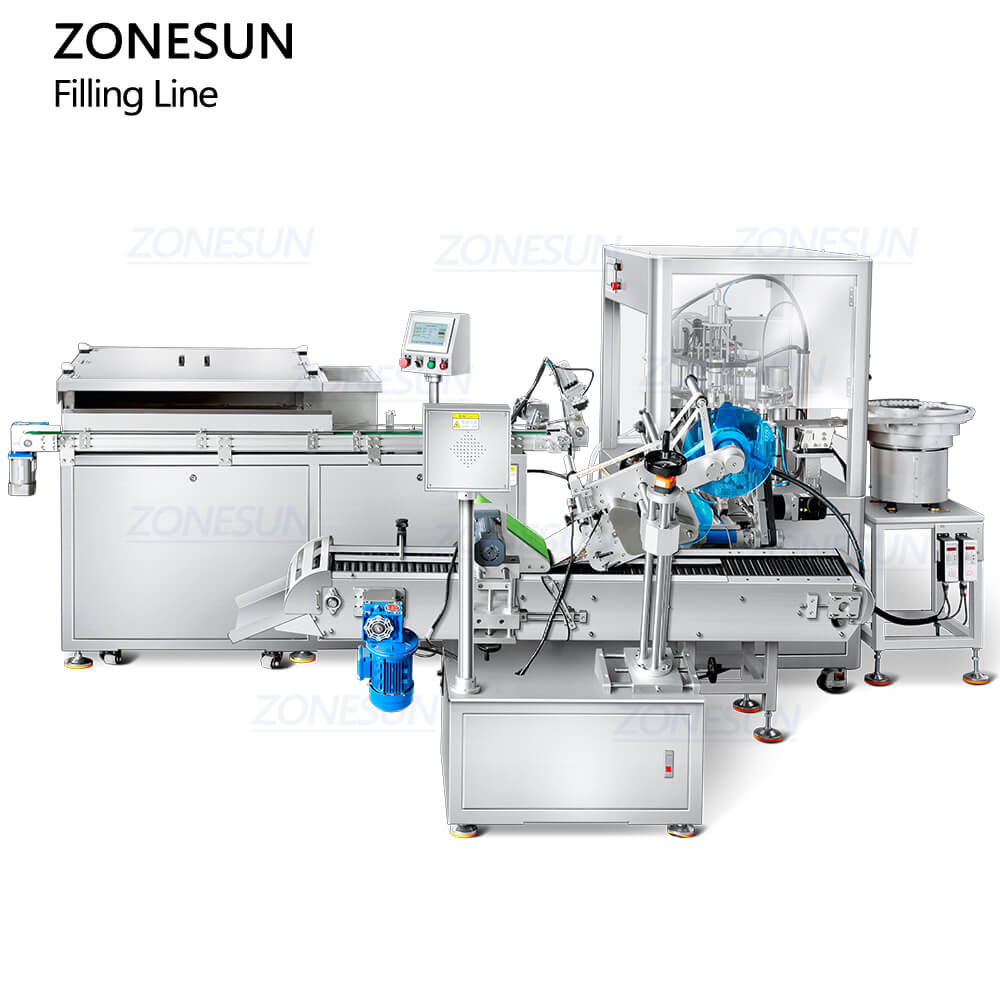

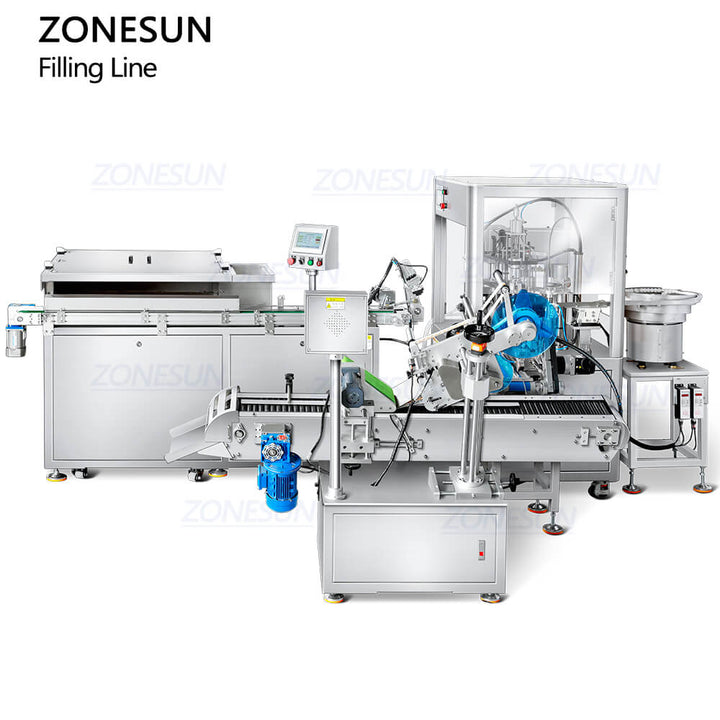

This is a fully automatic machine that integrates bottle unscrambling, filling, capping, and labeling for small bottles. It uses peristaltic pumps for hygienic, high-precision filling and a servo-driven capping system for stable performance. Suitable for 10–100ml liquids, it offers up to 40 bottles per minute and supports accurate labeling with optional date coding, making it ideal for cosmetics, personal care products, and essential oils.

Filling Capping Machine Parameter

- Machine Model: ZS-AFC28

- Voltage: 220V/110V 50-60Hz

- Power: About 3kW

- Production Speed: About 40 bottles/min

- Filling Range: 10-100 ml (Can be customized)

- Filling Pump: Peristaltic Pump

- Max Flow Rate: 6L/min(based on water)

- Suitable Bottle Size: Can be customized

- Bottle Cap Size: Can be customized

- Air Pressure: 0.5-0.7 MPa

- Machine Size: About 2050*1800*1500 mm

Labeling Machine Parameter

- Machine Model: ZS-TB823

- Power Supply: 110/220V 50-60HZ

- Working Speed: 60-170 bottles/min

- Labeling Accuracy: ±1 mm

- Suitable Labeling Object: Φ13-21 mm (Need to test for other sizes)

- Suitable Label Size: 20-100 mm(W)*20-130mm(H)

- Label Roll OD: Φ280 mm

- Label Roll ID: Φ76 mm

- Machine Size: About 2100*800*1400 mm(L*W*H)

- Package Size: About 2220*930*1520 mm(L*W*H)

- Package Weight: About 319 kg

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

Bottle Unscrambling Machine

It can arrange bottles in order and feed them to filling area. The machine is customized as your bottle size.

3 Filling Heads

Peristaltic pumps make liquid only pass through hoses, ensuring its cleanliness. The quantity of filling heads can be customized.

Cap Feeding Structure

It can pick up and feed caps to bottles, saving labor. The cap feeding structure is customized as your cap size.

Rotary Design

Filling, cap loading and capping are combined at one machine. It adopts cam control system, which can pack 40 BPM.

Bottle Orienting Structure

Can pick up bottles, make them in same direction and place them to conveyor of labeling machine automatically.

Labeling Structure

Suitable for semi-circle or full-circle labeling on small-diameter bottles. It can be equipped with date coder if needed.