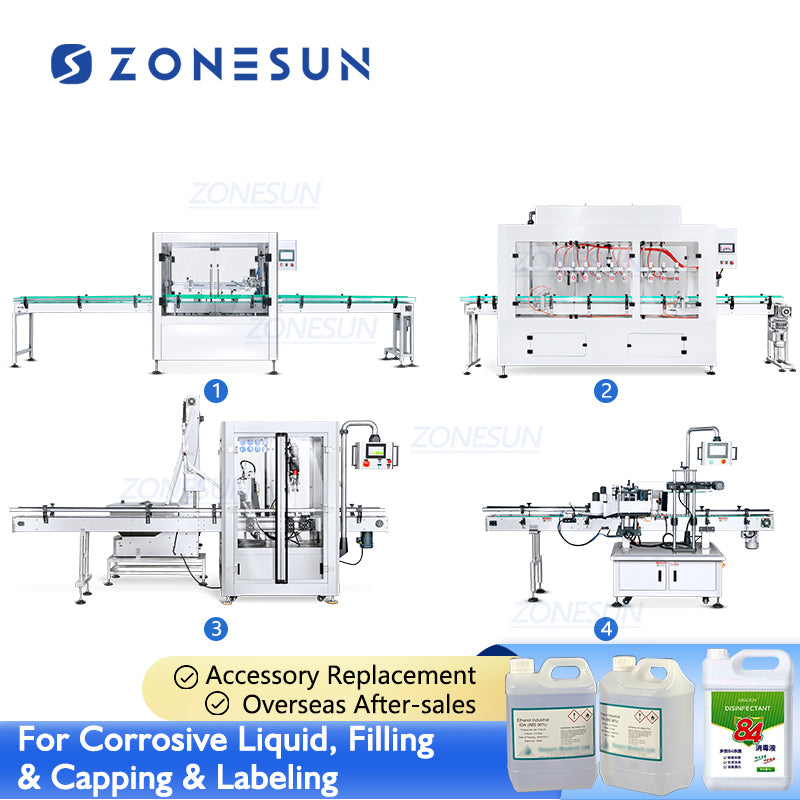

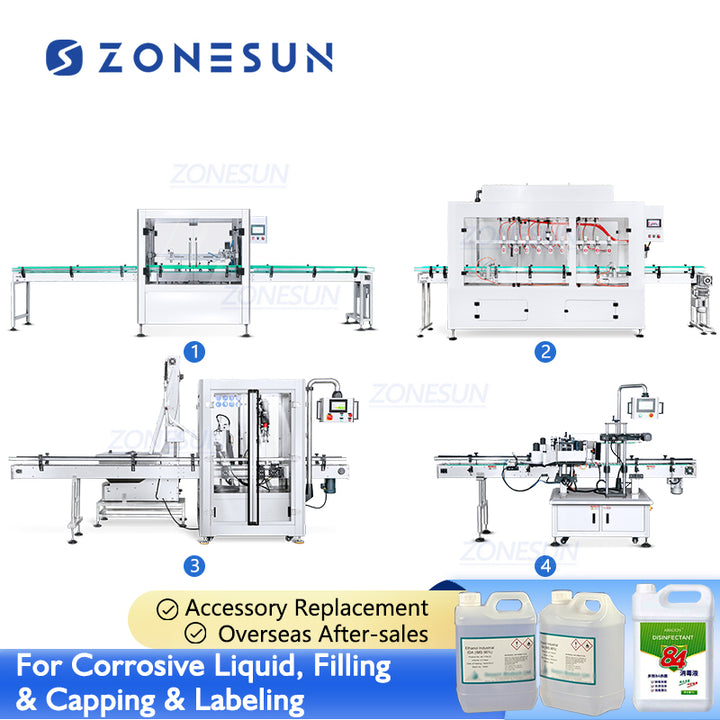

ZONESUN ZS-FAL180F5 Automatic 10 Heads 5L Container Pesticide Bleach Disinfectant Toilet Cleaner Chemical Corrosive Liquid Filling Capping Labeling Machine Line

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

- Local Service Location (Romania /Serbia /Kazakhstan/Mexico/Indonesia)

This filling system is designed for the automated filling of corrosive liquids into containers. It inlcude bottle rinsing machine, corrosive liquid filling machine, capping machine and labeling machine.This system are commonly used in industries where the handling of aggressive chemicals, acids, bleaches, and other corrosive substances is required.

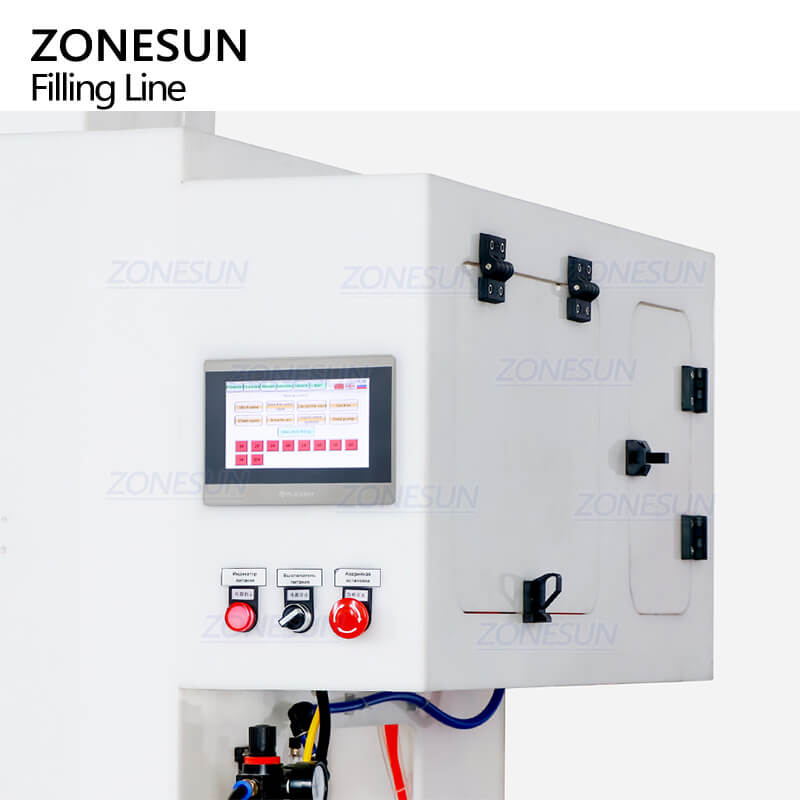

Parameter

Square Bottle Rinsing Machine

- Machine model: ZS-WB4

- Voltage: 380V 750W

- Suitable bottle size: Customize

- Working capacity: About 2000 BPH

- Machine size: About 5820*1900*1180 mm

- Machine weight: About 350 kg

10 Heads Filling Machine

- Machine model: ZS-YTCR10A

- Voltage: 110/220V 50-60HZ 1.5KW

- Air pressure: 0.4-0.7MPa

- Suitable bottle diameter: Φ30mm--φ120mm

- Suitable bottle height: 40mm--350mm

- Hopper size: About 2000*350*300mm(Customized)

- Filling range: 100ml--3000ml

- Filling speed: 600 BPH (based on filling volume)

- Machine dimension: About 4365*991*2298mm

Automatic Capping Machine

- Machine model: ZS-XG440F

- Machine voltage: 110/220V 50-60HZ 2KW

- Suitable cap size: 30-120mm(Can be customized)

- Suitable bottle height: Customized

- Air pressure: 0.7MPa

- Working capacity: 5-15BPM

- Machine size: About 2000*700*1600mm

- Machine weight: About 350kg

Automatic Labeling Machine

- Machine Model: ZS-TB300R

- Voltage: 220V/110V 50-60Hz

- Power: About 2500W

- Labeling Speed: About 10-60 bottles/min (depending on bottle and label size)

- Suitable Product Size: About 150-310mm(H)*150-250(W)

- Label Size: 15-300mm(W)*15-200mm(H)

- Label Roll Inner Diameter: Φ75mm

- Label Roll Outer Diameter: Φ350mm

- Machine Size: About 3018*1422*1859mm

*Specifications are for reference only and may vary by your product. Please confirm with us if required.

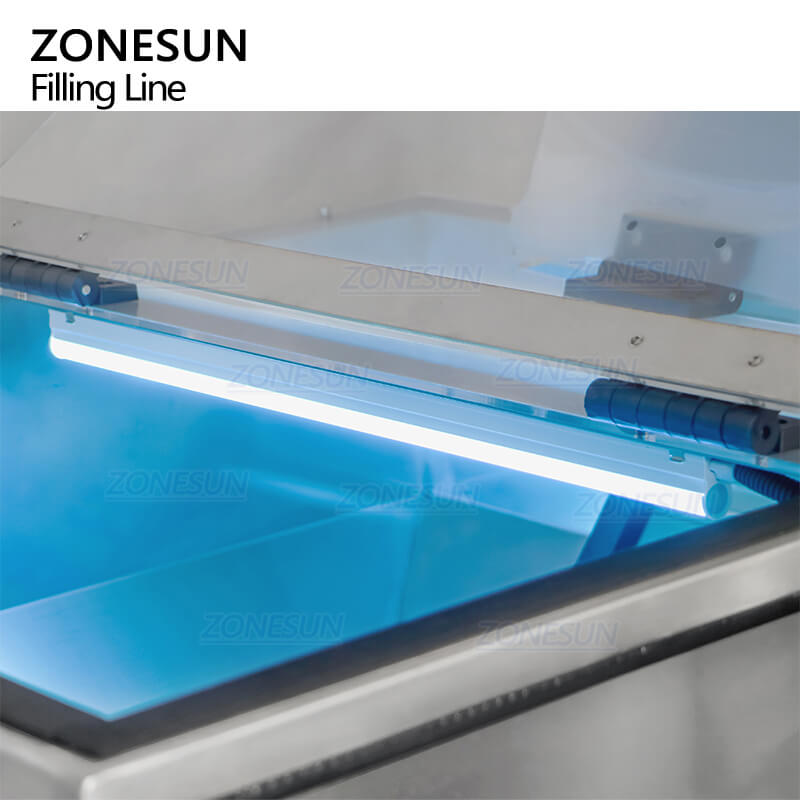

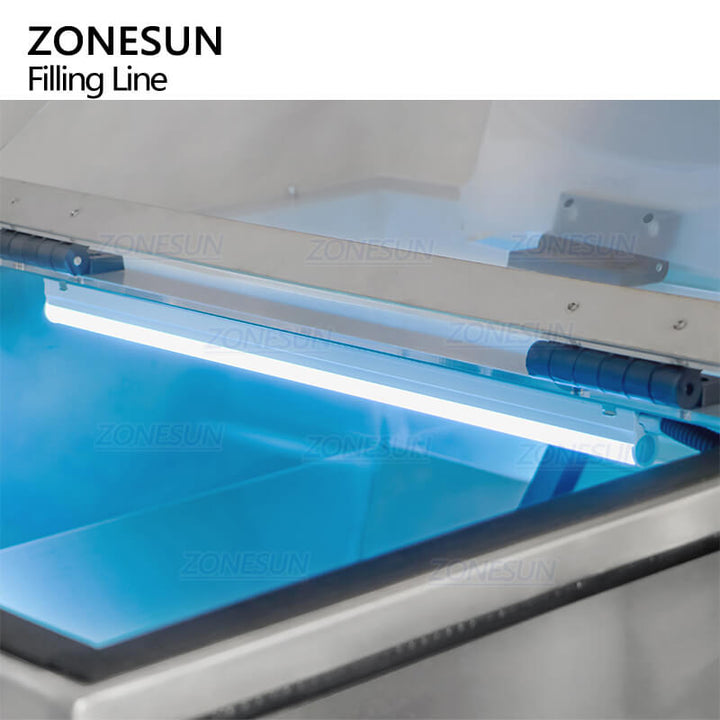

UV sterilization helps to kill bacteria, viruses, and other microorganisms that may be present on the caps, ensuring that they are clean and safe for use.The cap elevator can lifts caps from a hopper and moves them to the capping area, it saves working labor.

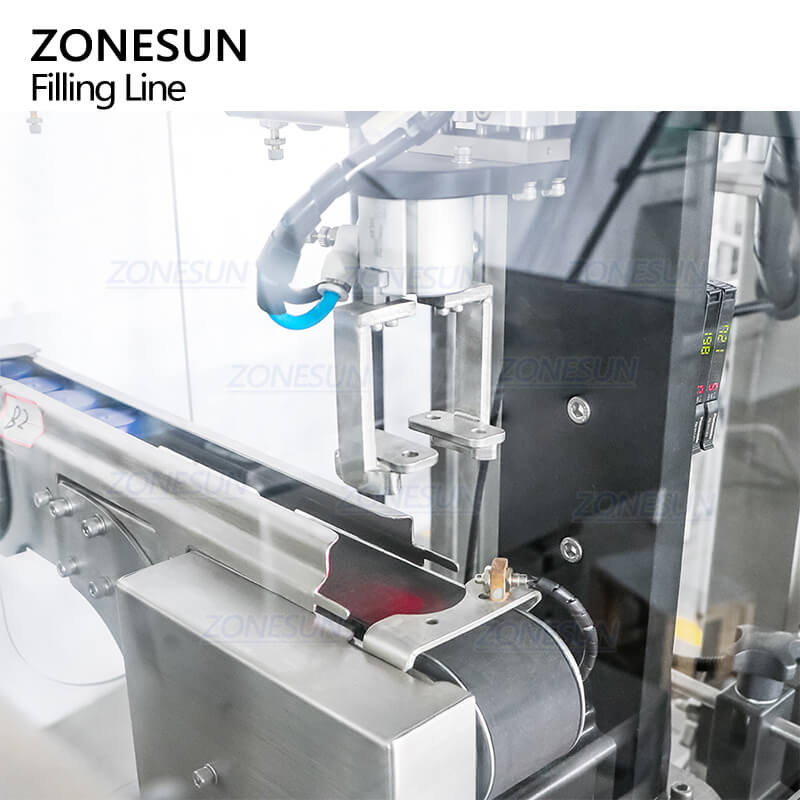

Misalignment of caps can lead to improper sealing or damage to the caps and containers. The cap placing structure helps prevent misalignment by guiding caps into the correct position before they are applied to the jerry cans.

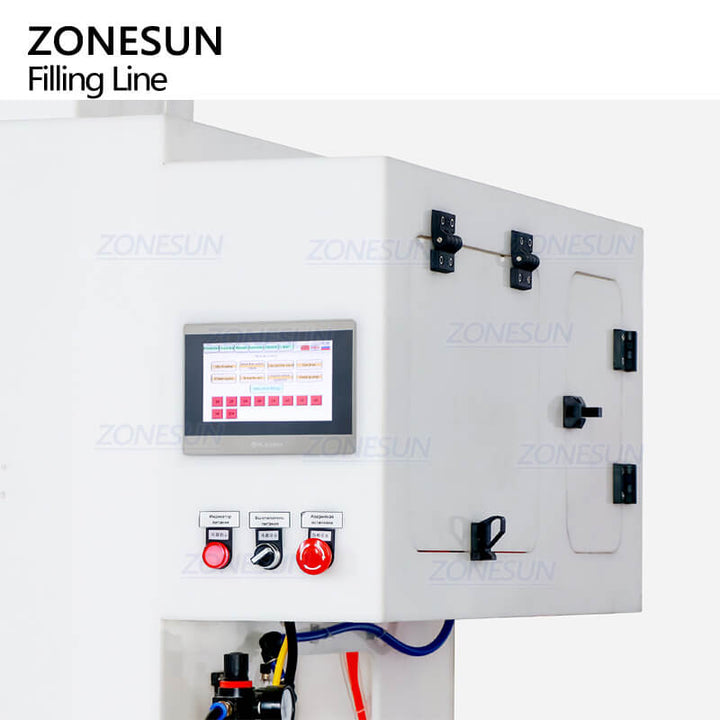

The capping work is controlled by servo motor, the capping torsion can be controlled more accurately. This precision allows for accurate positioning of caps onto jerry cans, improving packaging quality.Size of capping chuck can be customized according to cap size.

Designed for double sides labeling on larger flat bottle, one side of labeling structure can work separately, so it is also suitable for single side on the flat bottles.