Click  For Video

For Video

When filling,the dry powder filling machine will pump the air in the fire extinguisher cylinder to generate a negative pressure vacuum,suck the dry powder into the fire extinguisher through hose.After this,the fire extinguisher filled with dry powder will be transported to the capping machine by the conveyor belt for valvecapping.The line can work with other machines like nitrogen filling machine.

Parameter

Filling Machine

Machine model:ZS-FM6A

Machine power:About 4KW

Filling range:6-8kg (each head,can be customized as need)

Quantity of filling head:4

Working speed:About 500 bottles/hour

Machine size:About 1300*1300*2000mm

Package size:About 1540*1550*2190mm

Package weight:About 1000kg

Capping Machine

Machine model:ZS-XG22

Machine power:About 3.5KW

Suitable Valve Diamter:Customized

Quantity of capping head:2

Working speed:About 500 bottles/hour

Machine size:About 900*900*1850mm

Package size:About 1400*940*1340mm

Package weight:About 694kg

Labeling Machine

Machine Model:ZS-TB400

Machine Voltage:110/220V 50-60HZ

Suitable Product Diameter:15-120mm

Suitable Label Size:Customized

Labeling Speed:25-40 pcs/min

Labeling Accuracy:±1mm

Air Pressure:0.4-0.6MpA

Machine Size:About 2150*1100*1440mm

Machine Weight:About 222kg

Package Size:About 2150*1450*1590mm

Package Weight:About 470kg

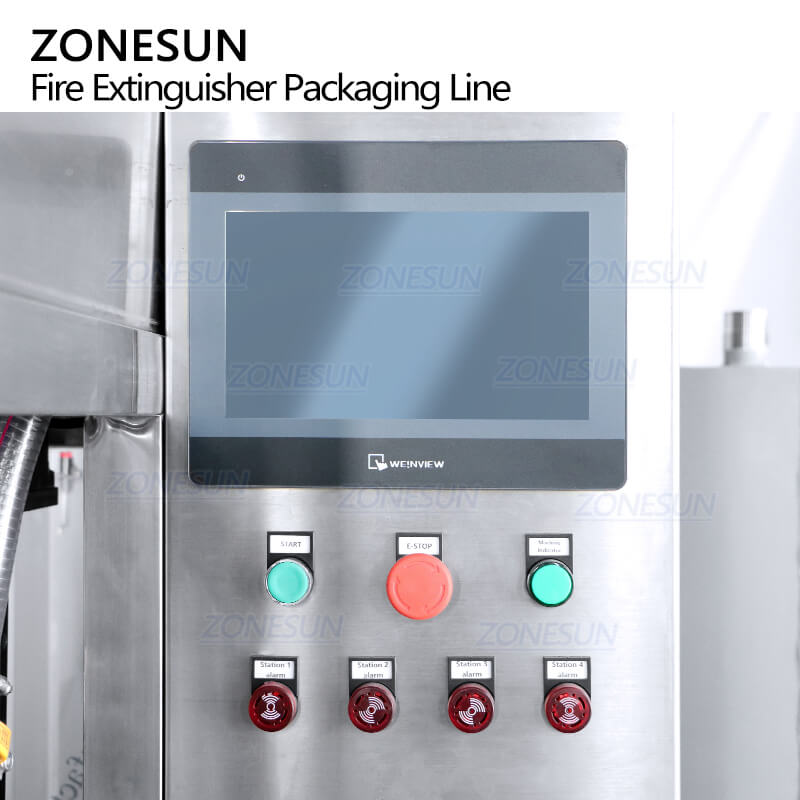

Equippied with touch screen control panel, this makes working data visual, it is more convenient to debug the machine and can watch the working status in real time.Different kinds of operation language can be customized as production need.

Multiple filling nozzles can be customized as production need.The filling machine is equipped with the weighing device, this can ensure the filling accuracy.The machine will pump the air in the fire extinguisher cylinder to generate a negative pressure vacuum to realize the filling work.

Equipped with powder recycling tank, the residual powder at the bottle mouth of the filling machine and the powder floating in the filling head are all extracted and returned to the recycling tank , and then returned to the powder tank after a series of procedures.This can reduce production cost and offer the solution of dust pollution greatly

The support device for valve screw is used to clean the powder on the bottle mouth and apply lubricating oil to the thread of the bottle mouth to ensure that the next capping work can be processed smoothly.The electric eye can detect passing by bottles and realize the automated production.

The valve capping machine has two working mode.The semi-automatic working mode and automatic working mode.The sensor can detect the position of the carry handle and finish the capping work.

Made of high quality stainless steel conveyor, it has larger weight capacity.This can transport products faster and more stably.

The working height of labeling structure can be adjusted according to production need, it label stickers by rotating the rubber cylinder, this kind of labeling methos is suitable for single side and double sides labeling.