A granulátum -töltőanyag kioszthatja és kitöltheti a granulátum -daganatokat (tartalmazza a tiszta szemcsés terméket vagy a granulátumok és a por keverékét) palackokba vagy tasakokba. Általában használják gabona csomagolására (például kávébab, dió, mogyoró, borsó, magvak), tea vagy száraz fűszer (granulátum és por keveréke).

Filling Machine For Other Material

Népszerű kapcsolódó kategóriák

Tudjon meg többet a granulátum töltőgépről

A szemcsés töltőgép mérési módja

A térfogat-pohara és a mérlegelés alapú töltő rendszer a granulátum töltőgép leggyakoribb mérési módszerei.

Volumetrikus csészéhez:

Állítható térfogat -csészék felhasználásával a granulált termékek rögzített térfogatának mérésére. A granulátumok a garatból esnek a csészébe, és amikor a gép fut, a kitöltött csészék a granulátumot a tartályba vagy a tasakba ürítik.

A térfogati csésze granulátum töltőanyag nem alkalmas egyenetlen sűrűségű, szabálytalan formákkal, törékeny textúrával, nagy értékkel vagy szigorú súlyszabályozásra szoruló termékekhez. Ha az anyag port tartalmaz, akkor a por kitölti a granulátumok közötti rést, ami ugyanolyan térfogat és megnövekedett hibák mellett következetlen súlyt eredményez. A térfogati csésze töltőgépek jobban alkalmasak szabadon folyó, egyenletes sűrűségű ömlesztett granulátumokra, például rizs és mung bab.

Mérlegelés alapú töltő rendszerhez

A gép több mérlegelő garatot használ, mindegyik a terheléscellákhoz csatlakoztatva. A granuláris termékeket vibráló csatornákon keresztül táplálják a garatba. A vezérlőrendszer kiszámítja a Hoppers legjobb kombinációját a céltömeg eléréséhez. A kiválasztott Hoppers egyidejűleg felszabadítja a granulátumot a tartályba vagy a tasakba.

Az ilyen típusú granulátum töltőgép magasabb töltési pontossággal rendelkezik, függetlenül a terméksűrűségtől vagy az alakjától. Rugalmasabb és alkalmassá válik szabálytalan vagy törékeny granulátumokhoz, például diófélékhez, harapnivalókhoz, szárított gyümölcsökhöz, vagy por és granulátum, például száraz fűszer keverékéhez. Általában a mérőfejek mennyisége testreszabható a működési sebesség javításához.

A szemcsés töltőgép alkalmazható csomagolása

A szemcsés termékeket általában palackokba, üvegekbe vagy tasakokba csomagolják, hogy megfeleljenek a különböző termelési követelményeknek. ZONESUN Különböző típusú granulátum -töltőgépet kínál a különféle termelési igények kielégítésére.

Tasak/tasak kitöltő tömítőgép

Az előkészített tasakokhoz:

Kínálunk tasak -töltőgépet, amely befejezheti a tasak etetését, a tasaknyílásokat, a granulátum -töltést és a tasak tömítését. Néhány tasak -töltőgép néhány gépi alkatrész megváltoztatásával különféle méretű tasakokhoz illeszkedik.

Roll-film táskákhoz:

A VFFS csomagológépet ajánljuk a granulátumok csomagolásához olyan tasakokba, mint a dió snackek, a tea és a bab.

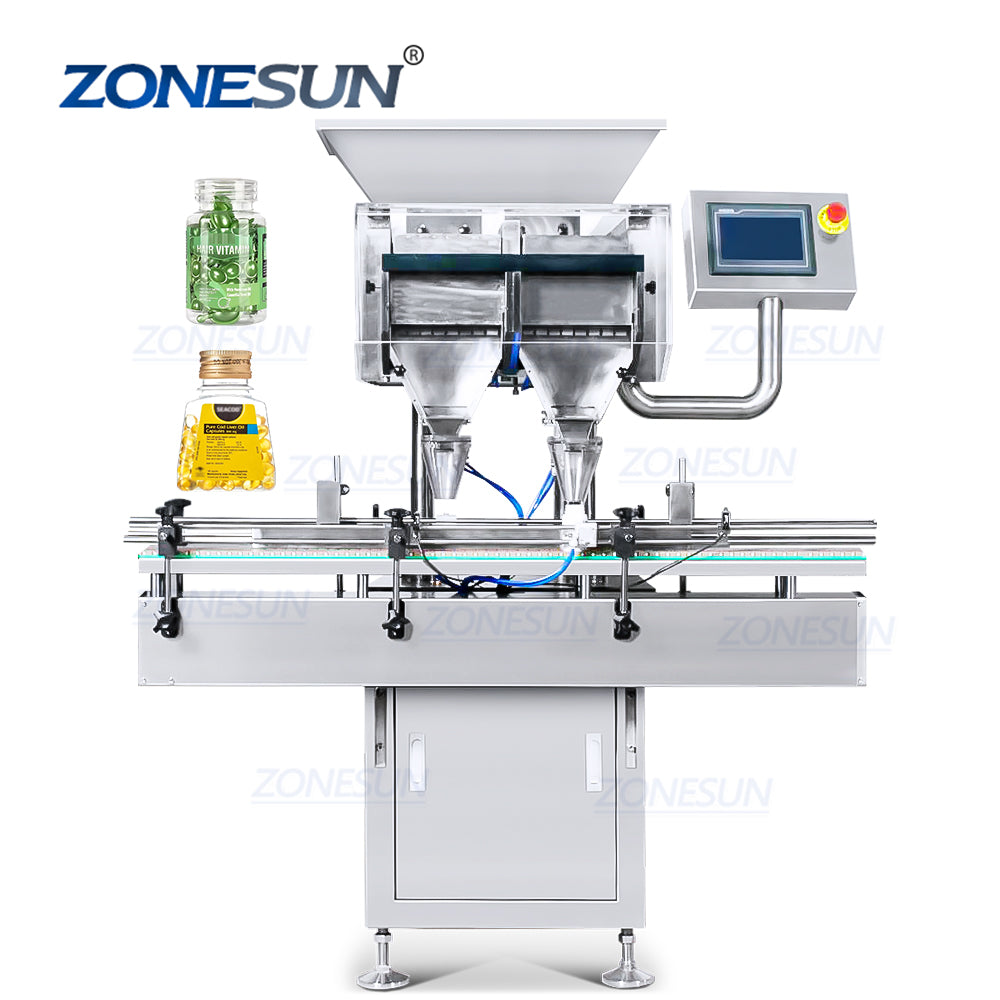

Palack/edény töltőgép

A lineáris palack töltőgépek magasabb működési sebességet biztosíthatnak, és bizonyos gépi alkatrészek enyhe beállításai megfelelhetnek a különböző méretű vagy magasságú palackoknak, általában nem kell a gép alkatrészeinek cseréje.

GYIK

K: Hogyan lehet beállítani a töltési térfogatot a térfogat -csésze töltőgéphez?

A csésze méretének vagy a csésze mélységének megváltoztatása elérheti a töltési térfogat megváltoztatásának célját. Általában a működés beállíthatja a mérőpohár mélységét az alsó lemez mozgatásával a csésze mélységének szabályozásához. Egy másik módszer a chaging csészék. Ha a töltési kapacitás nagymértékben eltérő, akkor cserélhető csészéket kínálnak a termelési igények kielégítésére.

K: Használható -e a száraz fűszer keverékére?

Valójában ez a száraz fűszerétől függ. Általában azt javasoljuk, hogy keverőkészüléket használjon az eredeti anyag keverésére, először ellenőrizze a keveréket a keverés után. Ha a keverék nagy részét tartalmazza a durva vagy varás anyagok, akkor azt javasoljuk, hogy a mérlegelés alapú granulátum töltőgép. If the mixture has only a small proportion of coarse materials but a higher proportion of powder, then auger filling machine will be better.