Смешивание резервуара может комбинировать или смешивать различные материалы, часто жидкости, чтобы создать однородную смесь. Смешивание НДС подходит для различных отраслей. Как химическая обработка, продукты питания и напитки, косметика. Конструкция и особенности смешанных резервуаров могут варьироваться в зависимости от материала для смешивания (конкретное применение или характеристики).

Тематические исследования

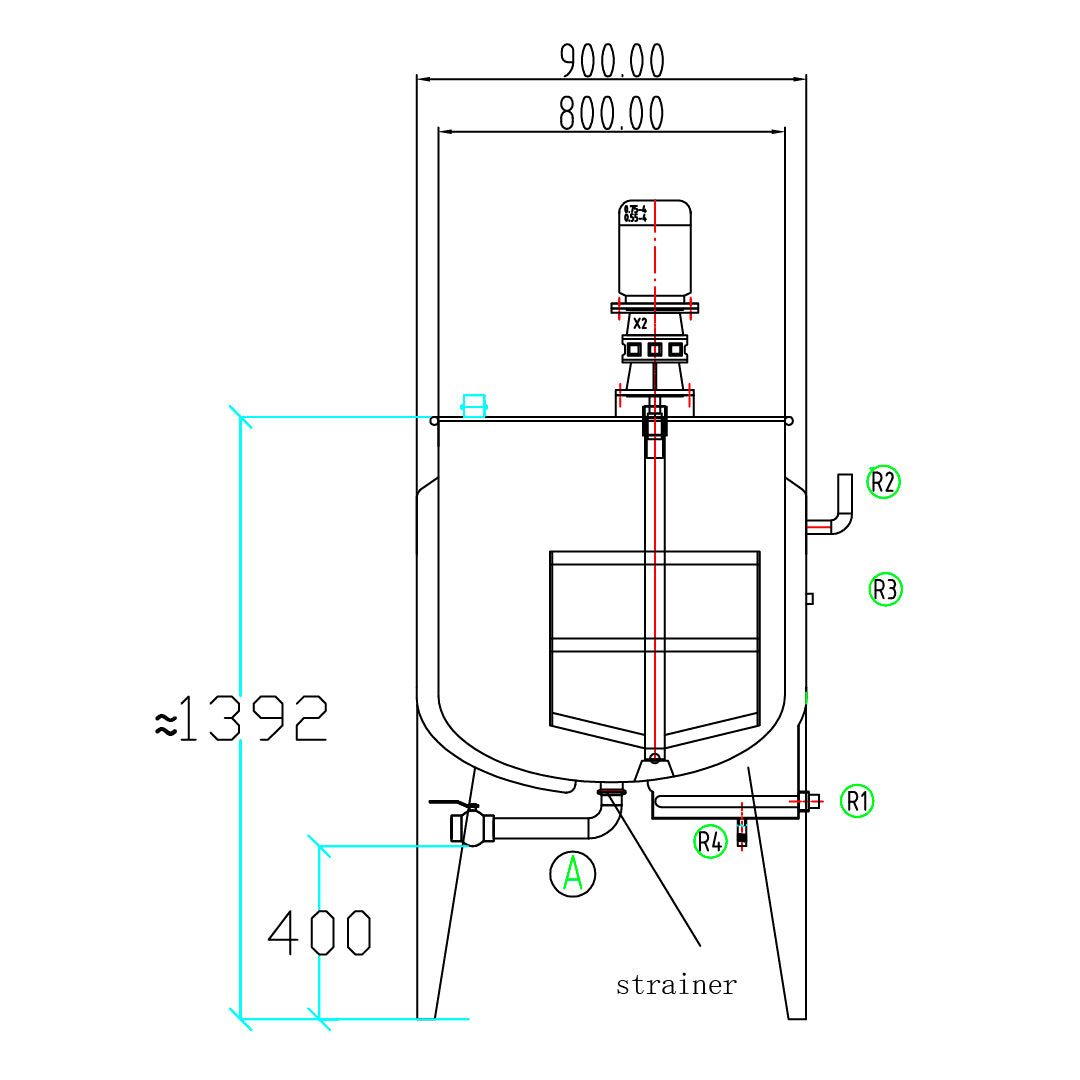

Смешивание резервуара для производства лосьона-USA

Требования: Смешанный бак должен иметь наклонную нижнюю конструкцию, оснащенную функцией отопления. Скорость перемешивания не должна быть слишком высокой, но должна иметь возможность поддерживать температуру лосьона во время производства, обеспечивая непрерывное смешивание для следующего шага производства. Вместимость: 200л.

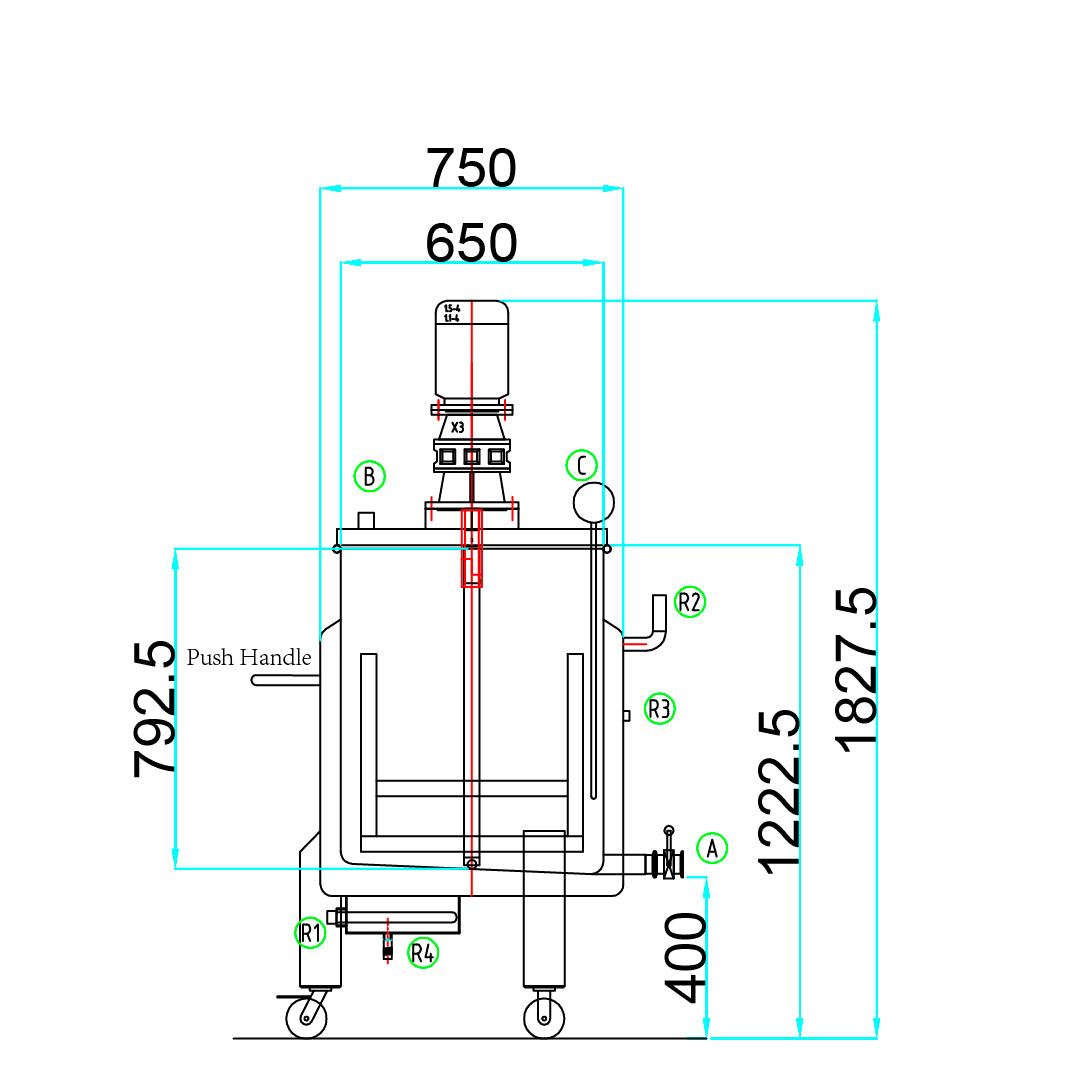

Смешивание резервуара для химических солей-австралия

Требования: Смешанный резервуар должен обеспечить непрерывное смешивание, а мешалка установлена на стороне, а не в центре. Он должен быть в состоянии подключиться к заполнению, иметь открытую крышку и быть оснащенным функцией фильтрации внизу. Емкость: 300L.

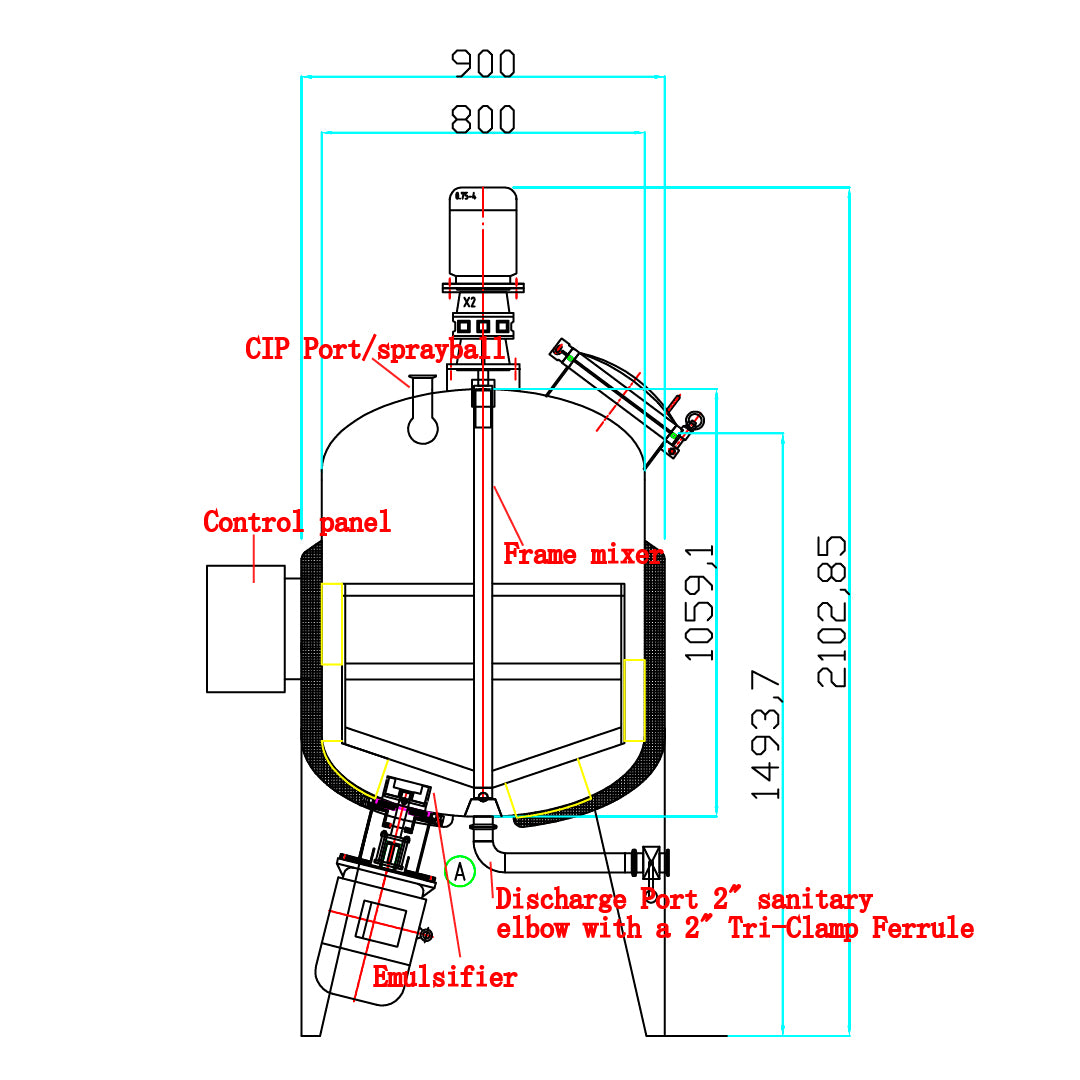

Смешивание танка для напитков

Требования: Система должна иметь более высокую мощность для быстрого растворения сахара и чая. Он должен быть оснащен брызги для подключения к системе CIP для быстрой очистки. Емкость: 500L.

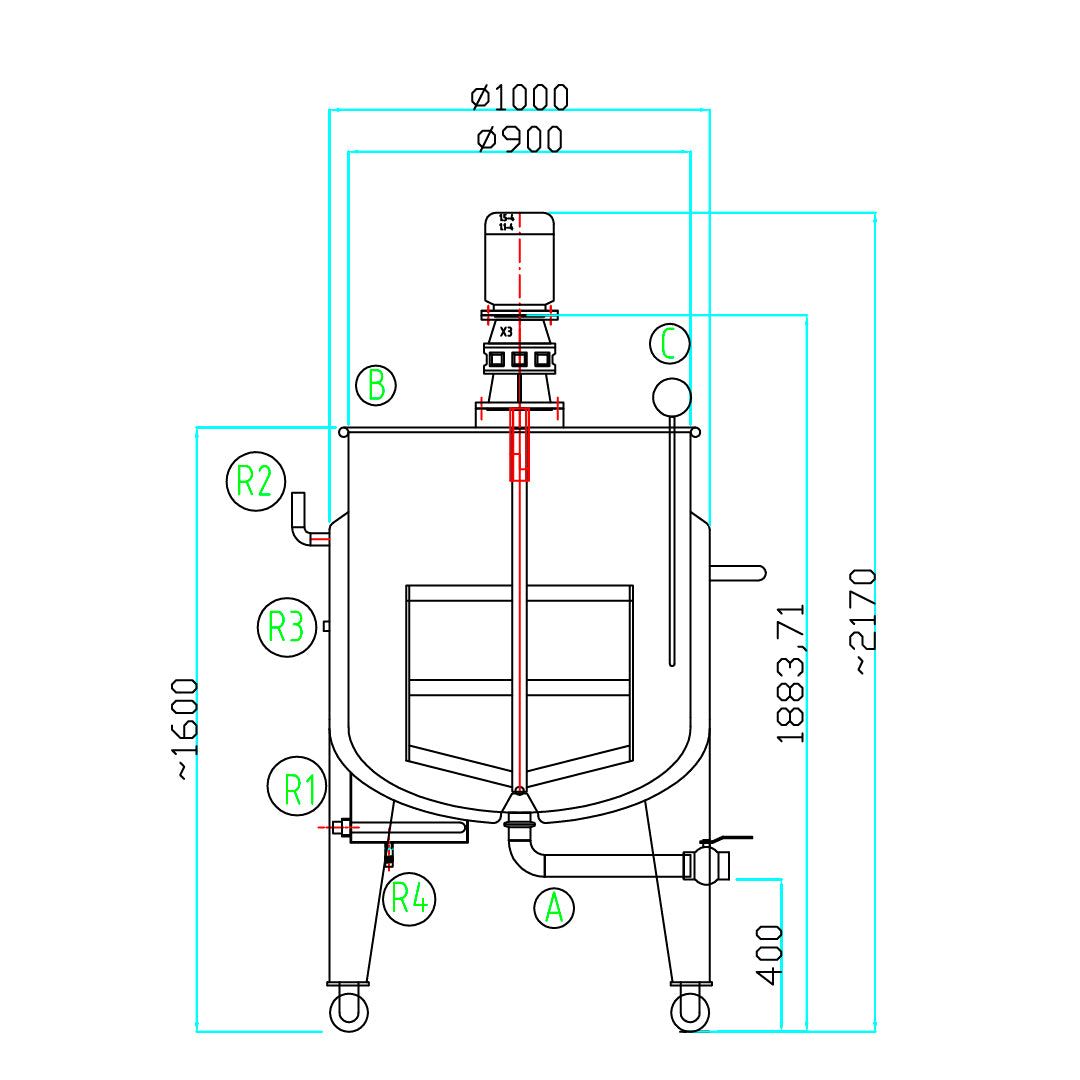

Смешивание танка для овощной глицерин-USA

Требования: Подходит для овощного глицерина с вязкостью 880 CPS, оснащенного брызги с брызгом для соединения с существующей системой CIP. Скорость вращения должна превышать 1700 об / мин. Емкость: 300L.

Часто задаваемые вопросы смешанного бака (сосуд смешивания)

Что такое смешанный танк?

Смешанный резервуар (также называемый смешанным ямой или сосудом смешивания) представляет собой сосуд, предназначенный для смешивания, эмульсификации или гомогенизации нескольких материалов. Он широко используется в таких отраслях, как продукты питания и напитки, химикаты, косметика, ежедневная химиката и фармацевтические препараты.

Каковы основные компоненты смешанного бака?

1. Корпус танка

2. Агитатор двигатель/коробка передач

3. Смешивание лезвий (якорь, весло, турбина, спиральный агитатор и т. Д.)

4. Поддержка рамы или базы

5. Входные/выходные порты

6. Опционально: отопление/охлаждающая куртка, система взвешивания, система CIP (чистого на месте)

Из какие материалы изготовлены танки?

Обычно нержавеющая сталь (SUS304 или 316), но также используются материалы PP в зависимости от свойств продукта.

Как выбрать правильный тип смешанного лезвия?

Учитывать:

1. Вязкость продукта

2. необходимо ли эмульгирование или дисперсия

3. Присутствие твердых частиц

4. Желаемые результаты смешивания (сдвиг, циркуляция, теплообмен и т. Д.)

Затем выберите конструкцию лезвия, такую как якорь, винт, тип кадры, турбину или ленту.

Может ли смешанный резервуар нагревать или прохладные материалы?

Да. Многие смешанные резервуары поставляются с курткой, которая позволяет нагревать масляной нагрев или циркуляцию охлажденной воды для поддержания определенных температур.

Легко ли чистить смешанный бак?

Да. Дополнительные системы CIP или конструкции быстрого высвобождения делают очистку и техническое обслуживание удобной.

Какие варианты емкости доступны?

От небольших лабораторных резервуаров (десятки литров) до крупных промышленных резервуаров из десятков тысяч литров доступны на индивидуальных возможностях.