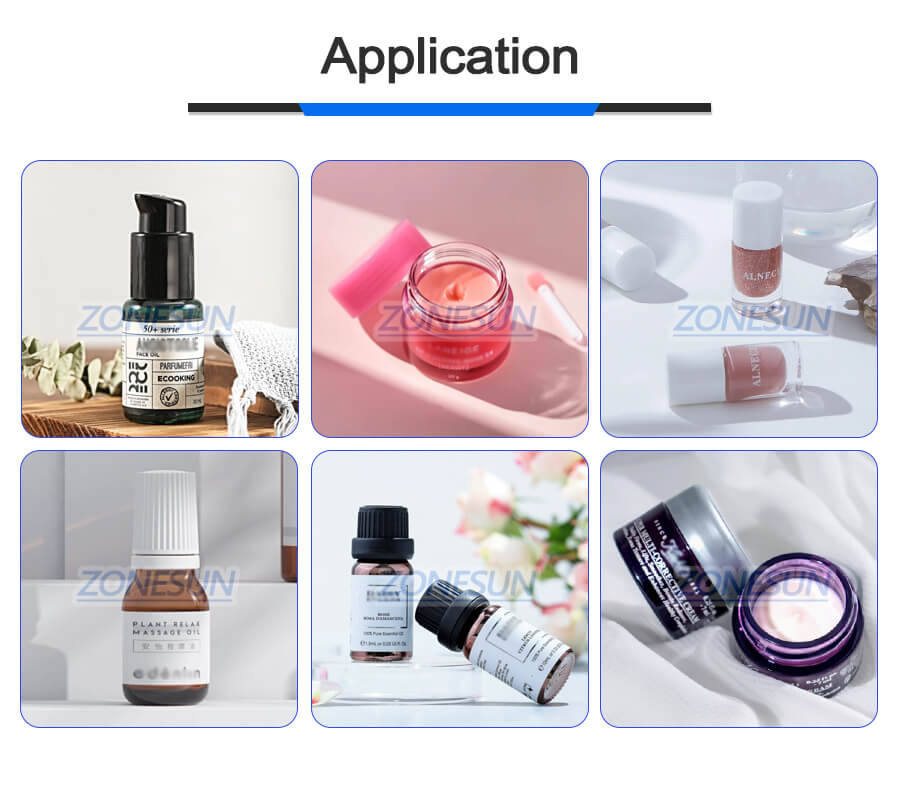

Equipped with peristaltic pump & ceramic pump, this monoblock machine is suitable for small volume mixtures that require separate filling of paste and liquid like gel.Or you can choose one of them to fill liquid or paste only. Capping chuck is customized according to cap size, this structure is controlled by servo motor, which has high working accuracy.

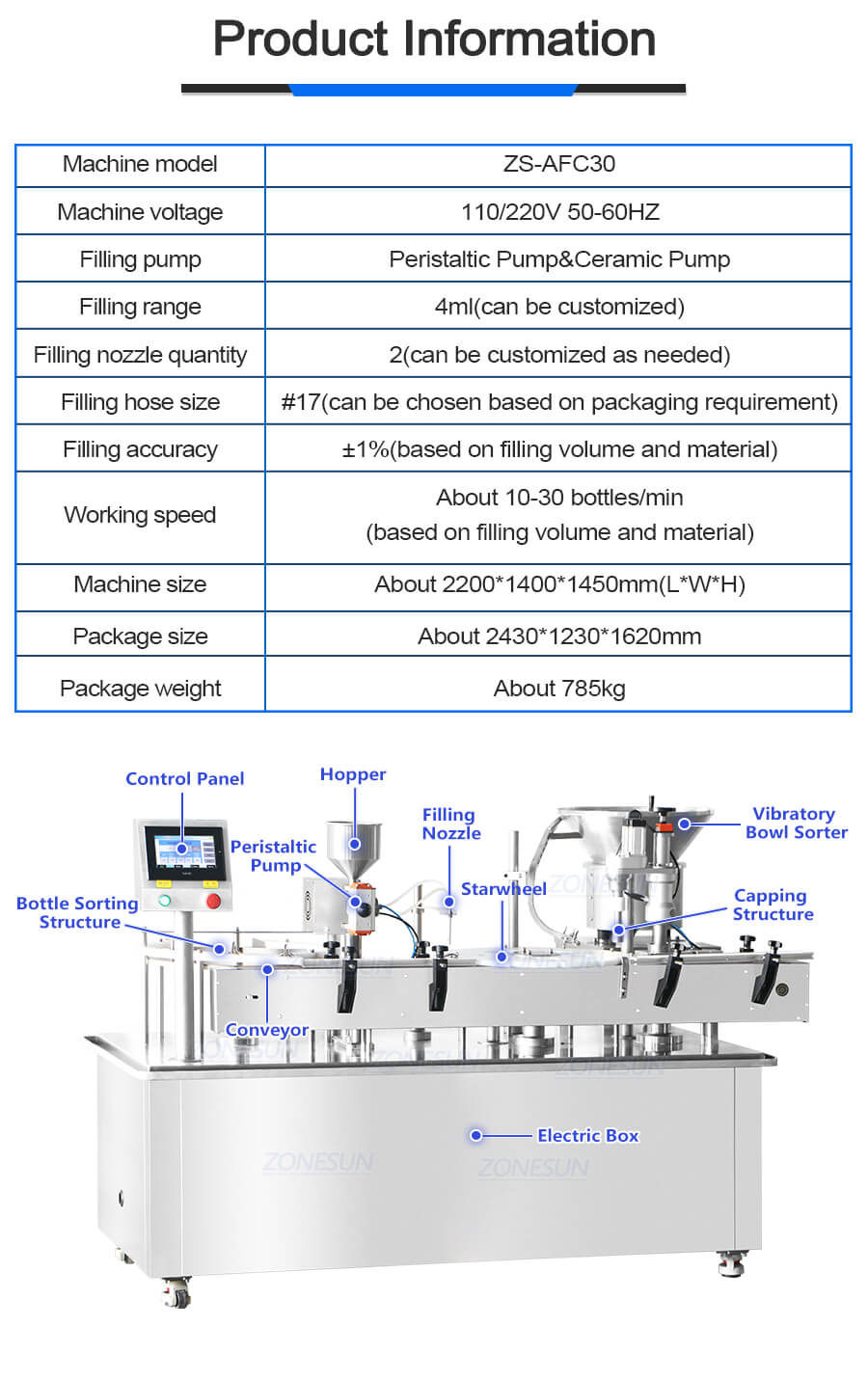

Parameter

- Machine model:ZS-AFC30

- Machine voltage:110/220V 50-60HZ

- Filling pump:Peristaltic Pump&Ceramic Pump

- Filling range:4ml(can be customized)

- Filling nozzle quantity:2(can be customized as needed)

- Filling hose size:#17(can be chosen based on packaging requirement)

- Filling accuracy:±1%(based on filling volume and material)

- Working speed:About 10-30 bottles/min(based on filling volume and material)

- Machine size:About 2200*1400*1450mm(L*W*H)

- Package size:About 2430*1230*1620mm

- Package weight:About 785kg

Equipped with touch screen control panel, customizable interface makes machine operation more convenient, operation language can be customized as needed.PLC control panel can shows working data directly.

Equipped with ceramic pump and peristaltic pump. The hopper can make filling material can be filled more smoothly.These two pumps can work together for mixtures that require separate filling of paste and liquid or work separately to fill liquid or paste only.

Equipped with bottle sorting structure, this simplifies machine operation, it can arrange bottles be in order automatically, saves working labor greatly.

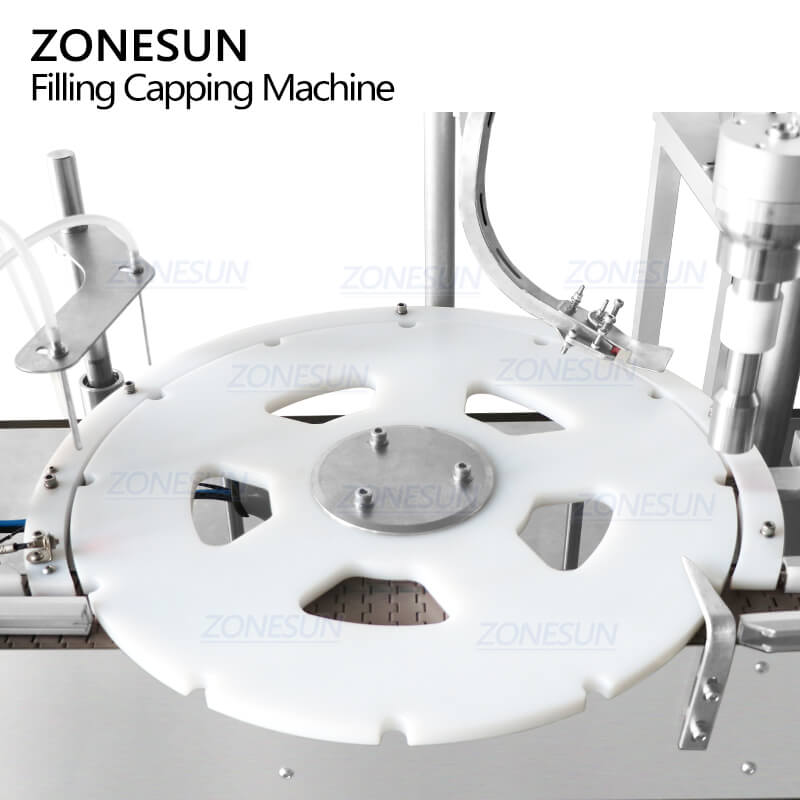

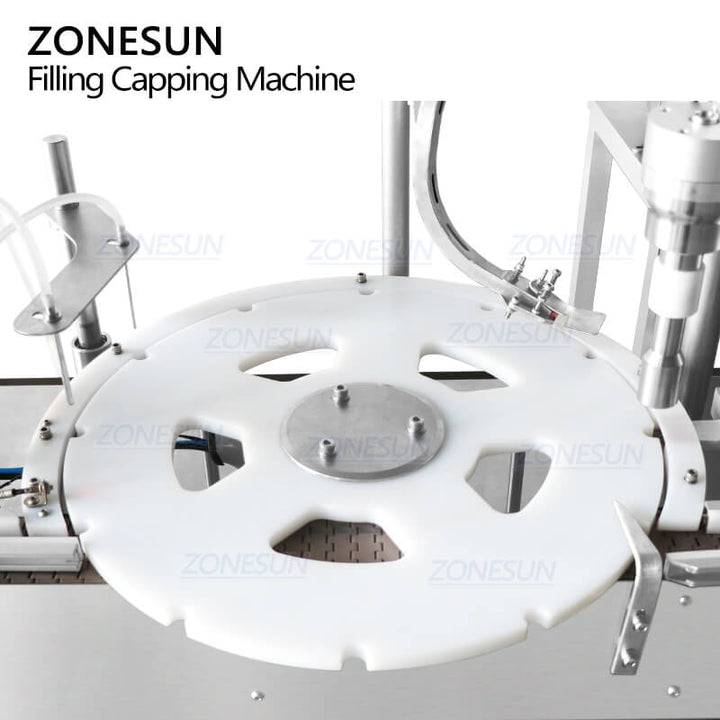

Filling and capping works are controlled by the cam working system, which improves working capacity and packaging accuracy.The size of starwheel is customized according to bottle size, it can prevent bottles from falling down during packaging work.

Customized vibratory bowl sorter can make caps be in order before capping work and convey them through guide rail, it reduces working error.