Machine Video

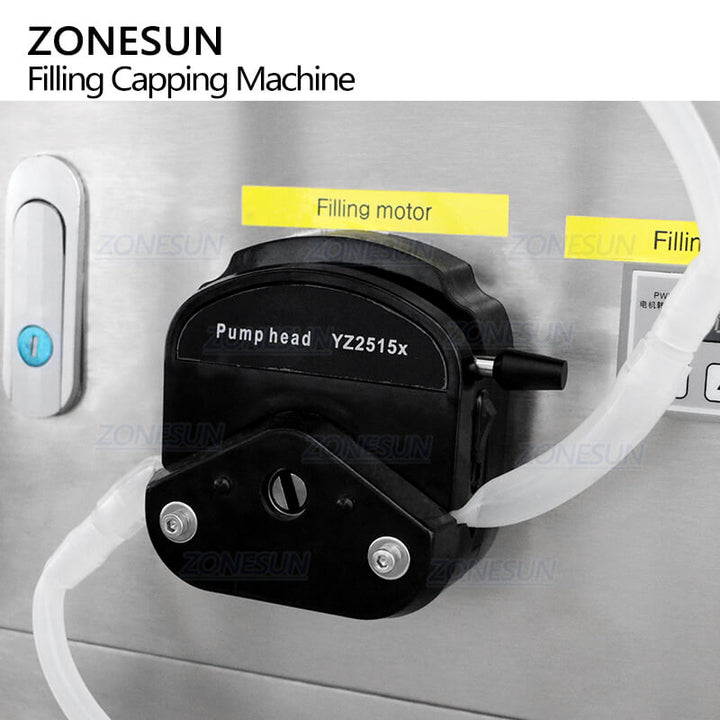

Equipped with peristaltic pump, this monoblock filling crimping machine has functions of bottle unscrambling, liquid filling and bottle crimping. It has high filling accuracy and suitable for chemical and cosmetic industry.

Parameter

- Machine model:ZS-AFC20

- Machine power:110/220V 50-60HZ 1kW

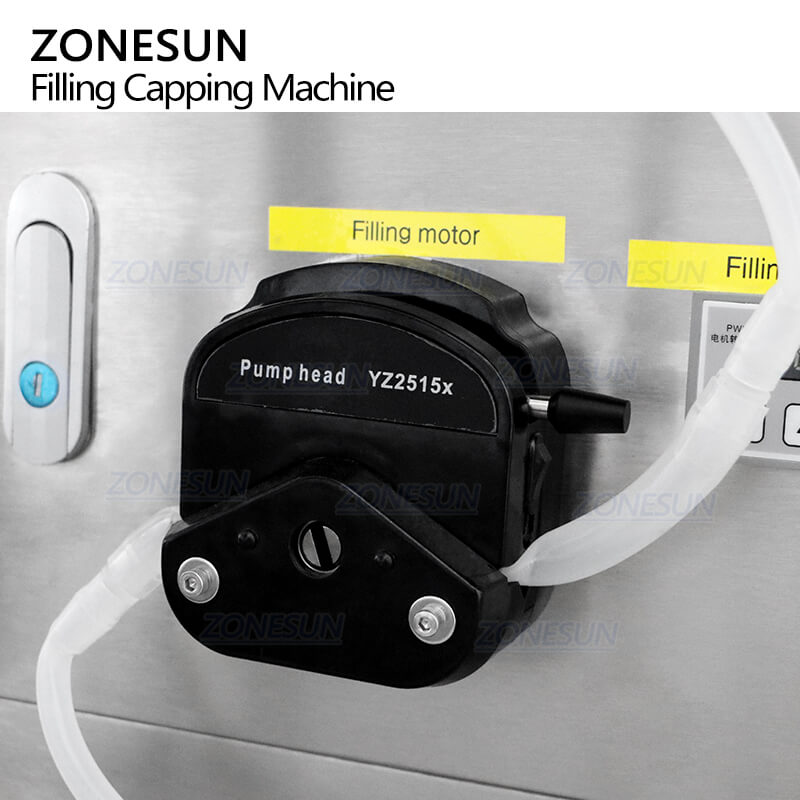

- Filling pump:Peristaltic Pump

- Max flow rate:2.5L/min

- Recommend Filling Volume:20-50ml(Customized)

- Working capacity:20-30bottles/min

- Suitable bottle height:About 45mm-60mm(Customized)

- Suitable bottle diameter:About 22mm(Customized)

- Suitable bottle mouth:About 19.5mm(Customized)

- Suitable cap size:H=10mm*φ=22mm(Customized)

- Machine size:About 1450*850*1050mm(L*W*H)

- Machine weight:About 195kg

- Package size:About 1190*990*1120mm(Main Machine)+About 880*500*570mm(Vibratory Sorter)

- Package weight:About 196kg(Main Machine)+About 124kg(Vibratory Sorter)

Equipped with touch screen control panel,the working parameter is visual which is more convenient to debug.The operation language can be customized according operation need.

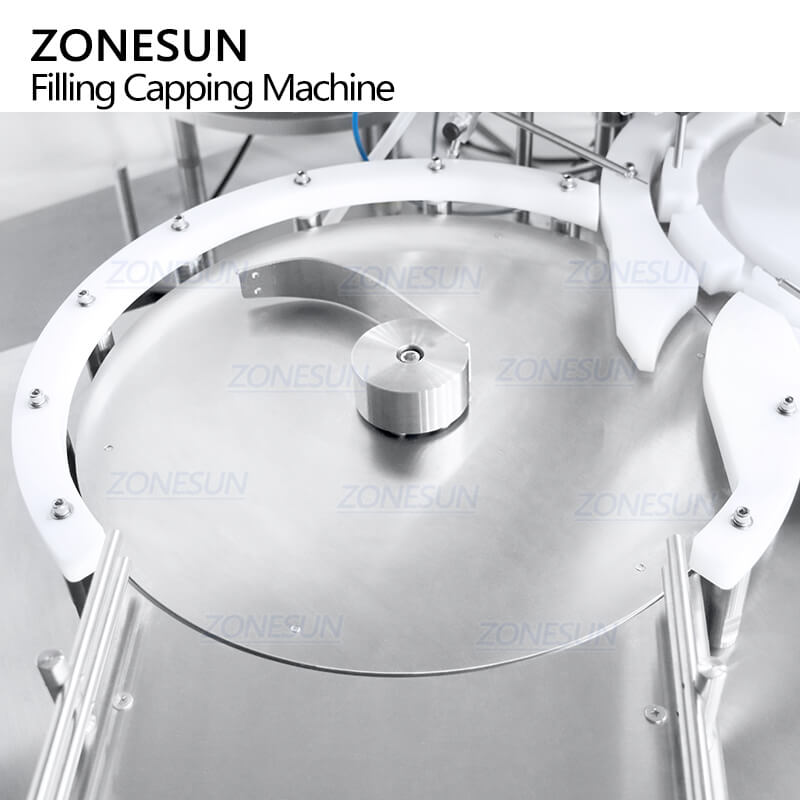

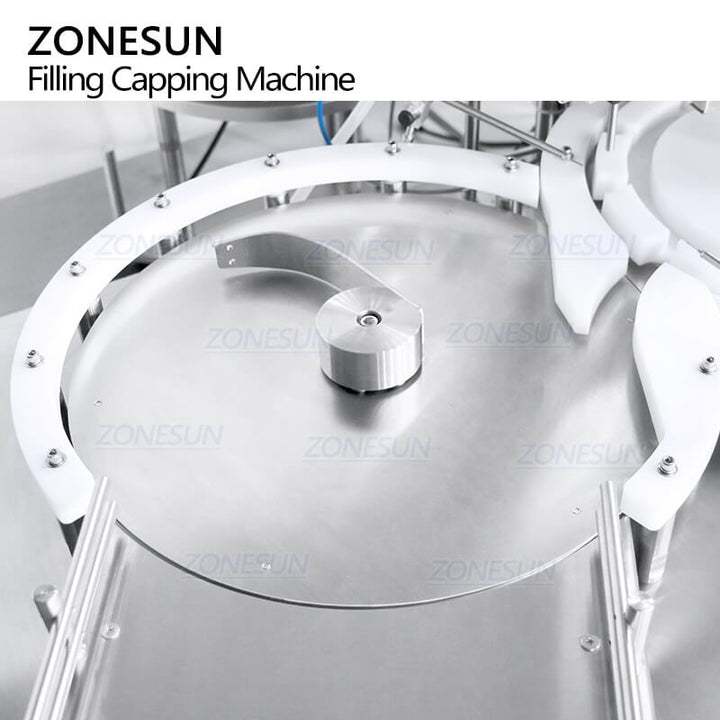

Equipped with bottle unscrambling structure,it can make bottles be in order before filling and capping work, it reduced production error.

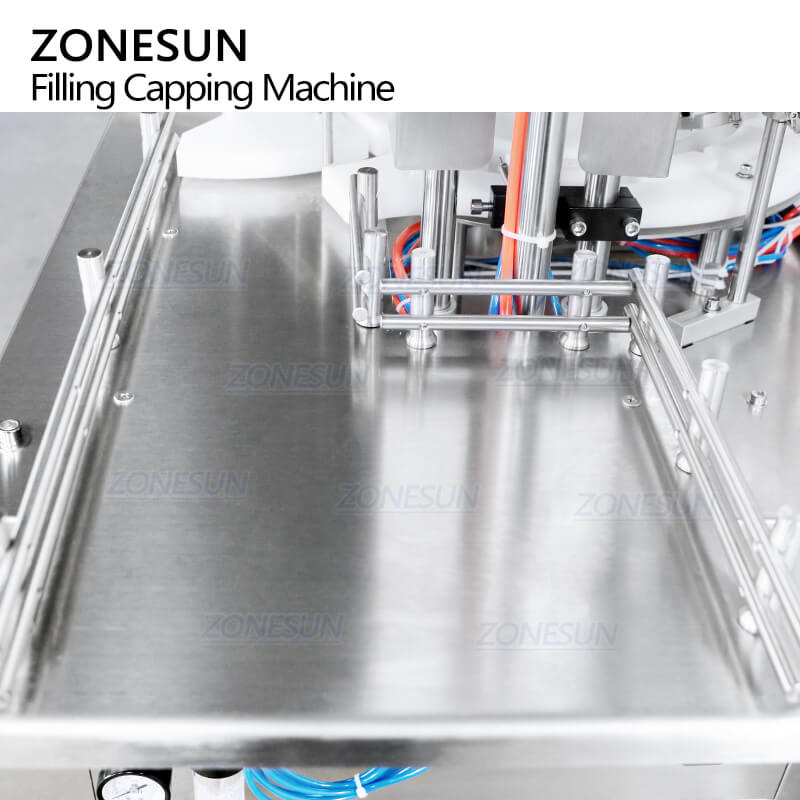

Equipped with peristaltic pump, the filling material only pass through hose and filled into bottles, this can ensure the filling material as clean as possible.

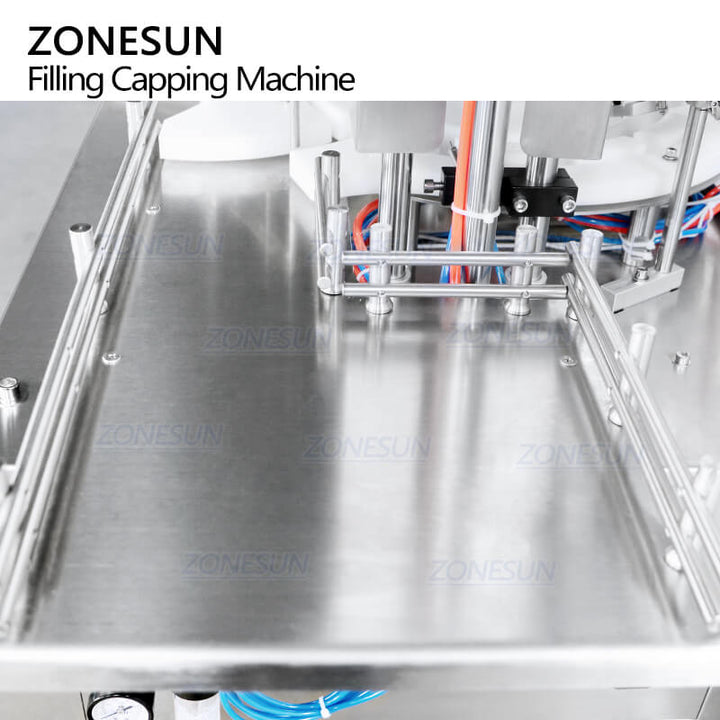

There is an electric eye of each working structure,it is use to detect passing by bottles and realize automated work.It reduce production error.

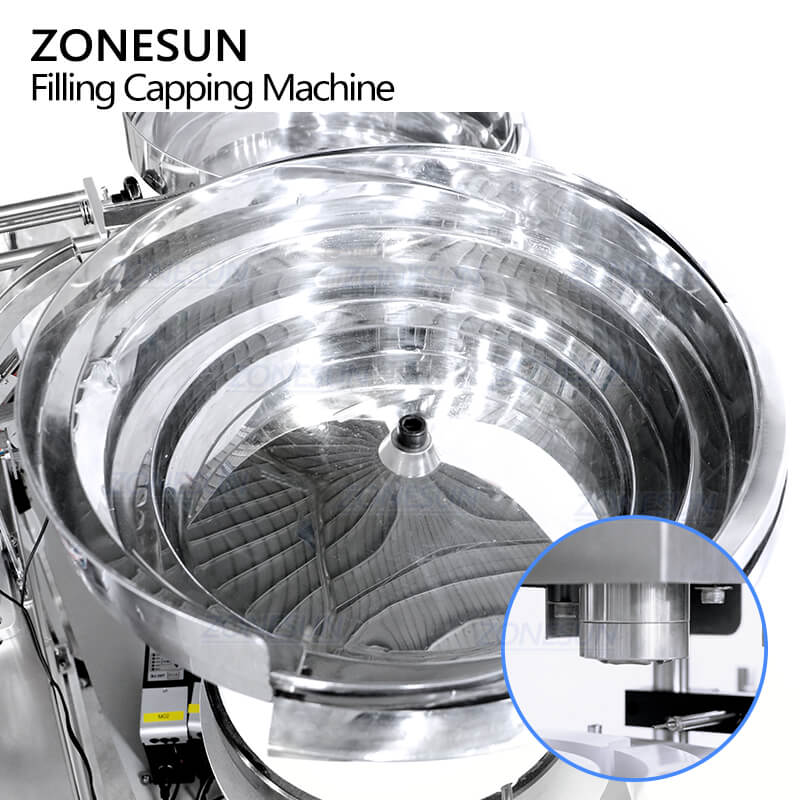

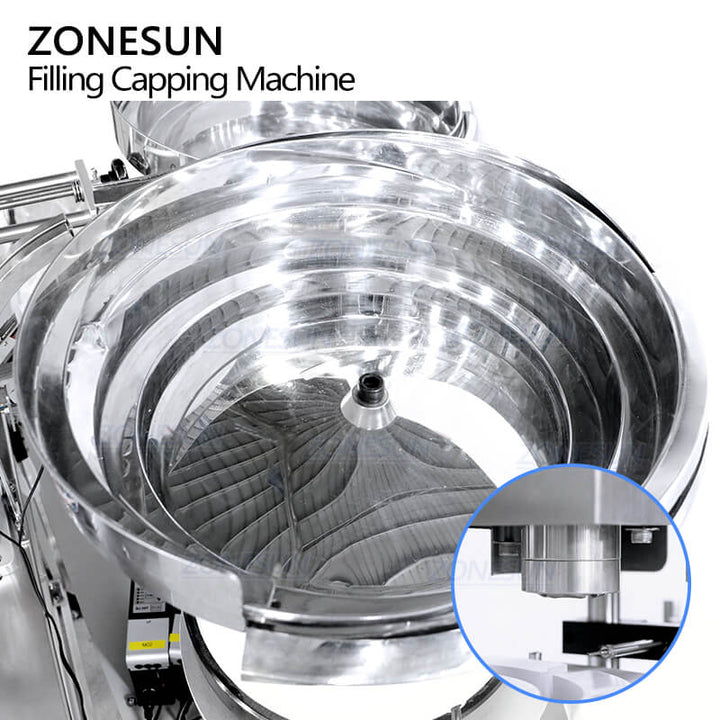

Equipped with vibratory bowl sorting machine to realize automated cap feeding,the capping structure is customizes according to bottle opening size,this can reduce production error.

The large bottle sorting structure can collect finished products together,it reduce the production labor and make it more convenient to move to next production process.