ZONESUN Automatic Cap Mineral Water Beverage Bottle PVC Film Sleeve Label Machine

ZONESUN Automatic Cap Mineral Water Beverage Bottle PVC Film Sleeve Label Machine

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

- Local Service Location (Romania /Serbia /Kazakhstan/Mexico/Indonesia)

Description

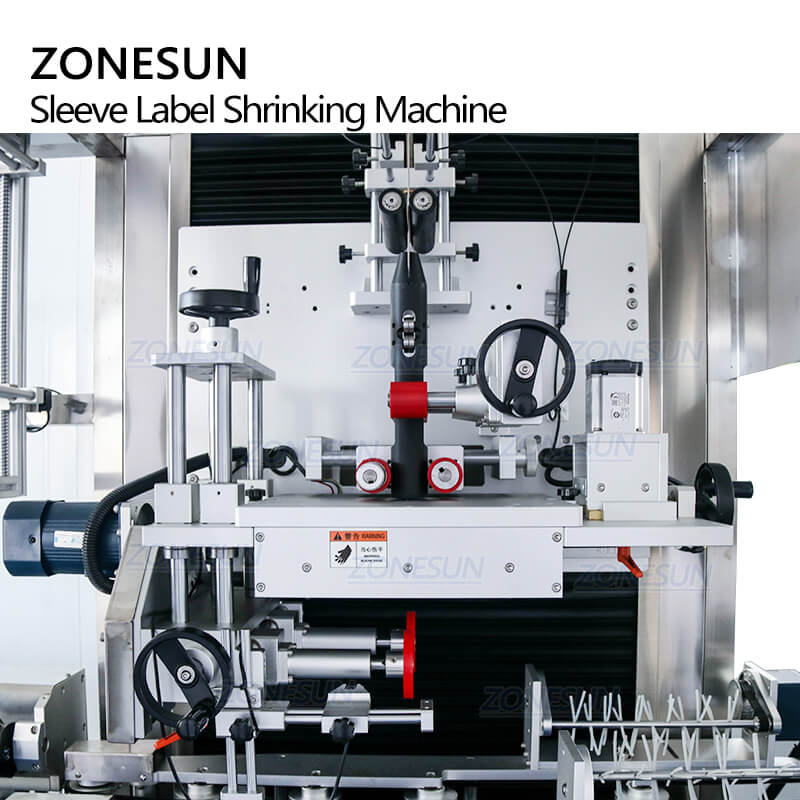

The sleeve labeling machine is suitable for packaging various bottle types of juice, tea beverages, dairy products, purified water, condiments, sports drinks, etc. This machine has high accuracy of sleeve label position, and it can highlight the bottle and perfect the bottle shape after shrinking. The whole machine adopts stainless steel protective frame cover and aluminum alloy rigid frame, which is stable and does not rust. Suitable for round bottles, square bottles, oval bottles, etc.

Parameter

Sleeve Label Machine

Machine model:ZS-STB150

Bottle diameter range:φ28mm-φ125mm (can be customized)

Bottle height:30mm ~ 280mm (can be customized)

Label length:30mm~250mm (can be customized)

Label thickness:0.03 mm ~ 0.13 mm (PVC, PET, OPS, materials are all available)

Sleeve standard error:+1.5mm

Paper tube inner diameter:5"~10" (can be adjusted)

Machine speed:150 bottles/min (based on label length)

Voltage:220V Single Phase

Power:15KW

Conveyor belt:standard 2M

Machine size:About 2950*10301870mm(L*W*H)

Machine weight:About 464kg

Shrinking Machine

Tunnel length:About 1800mm

Tunnel width:About 395mm

Tunnel height:About 360mm

Suitable bottle diameter:≤80mm

Conveyor height:About 900mm

Machine size:About 3050*480*1330mm(L*W*H)

Machine weight:About 86kg

Package size:About 1905*610*1720mm

Package weight:About 143kg

The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation,ensure the labeling effect,it helps save a lot of time.

Equipped with high quality electric eye,It can be used to detect bottles and control the machine to work or not,it realize the automated working and helps to improve working accuracy.

Suitable for different shapes of bottles,the label feeding mechanism can automatically work once the system detect bottles.This machine is suitable for 30mm ~280mm height bottles,and we can customized the machine according to your needs.

The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect.It is also with soft brush which is used to improve the sleeving effect for the next film shrinking process.

The pipe is used to exhaust waste steam and ensures the shrinking quality.The heating tunnel is made of high quality materials,it can ensures the film can be shrunk equably.

Three-layer air bump hole design,the jet length and direction can be adjusted.It is also with temperature display,this helps you can control the working situation in real time.