The hot melt glue labeling machine is a compact and efficient device used for applying labels to various products. It uses hot melt adhesive to securely attach labels, ensuring they stay in place even in challenging environments. With its precise and automated labeling process, this machine offers high-speed production and consistent labeling quality in beverage, daily chemical and cosmetics industries.

Parameter

Machine Model:ZS-GTB12

Voltage:380V 50Hz 3 Phase

Power:8kW

Station:12 Stations(Can be customized)

Labeling Speed:About 12000-15000BPH

Labeling Accuracy:±1mm

Max Label Size:140mm(W)*430mm(L) (Can be customized)

Label Roll Outer Diameter:Max 600mm

Label Roll Inner Diameter:152mm

Gluing Temperature:120-160℃

Type of Labels:OPP film labels, paper-plastic composite film labels, paper labels.

Conveyor Height:1050±30mm(Adjustable)

Conveying Speed:30m/min(Adjustable)

Machine Weight:About 2000kg

Machine Size:About 3100*1350*2100mm(L*W*H)

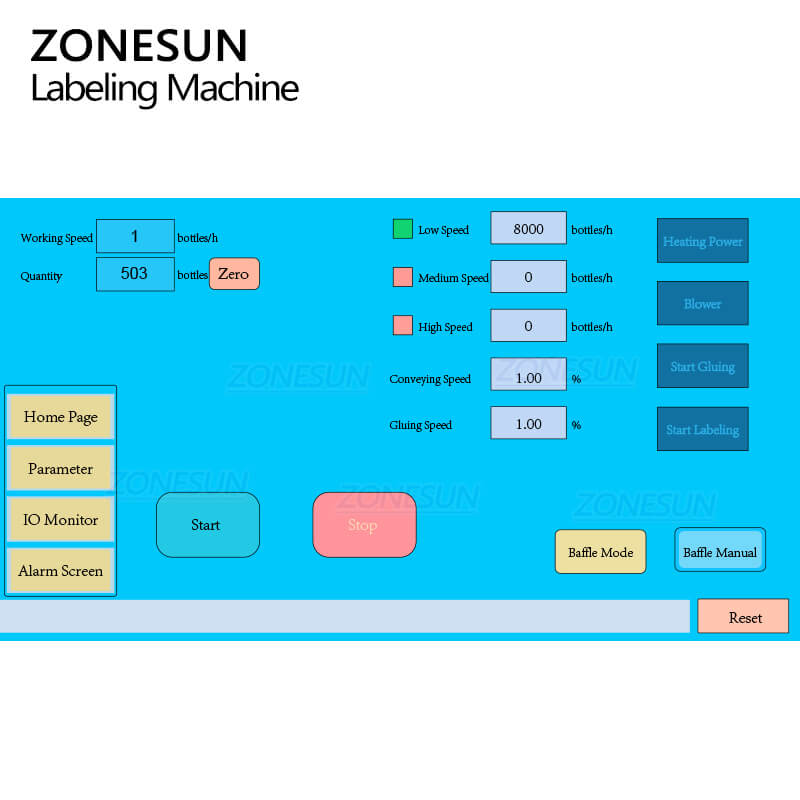

Equipped with PLC panel, it is convenient to set and adjust working parameters. The language of panel can be customized as your need.

This component is designed for gluing the label ends and attaching them onto bottles. The gluing temperature is 120-160℃.

Designed with 12 stations, it can label bottles quickly, greatly improving efficiency. The quantity and size of fixing molds can be customized according to your products.

The rotary plate is designed for conveying bottles before and after labeling process, saving labor cost. It can be customized as production need.

The sensor is designed for detecting labels and control the machine to output labels accurately. Its sensitivity can be adjusted according to production need.